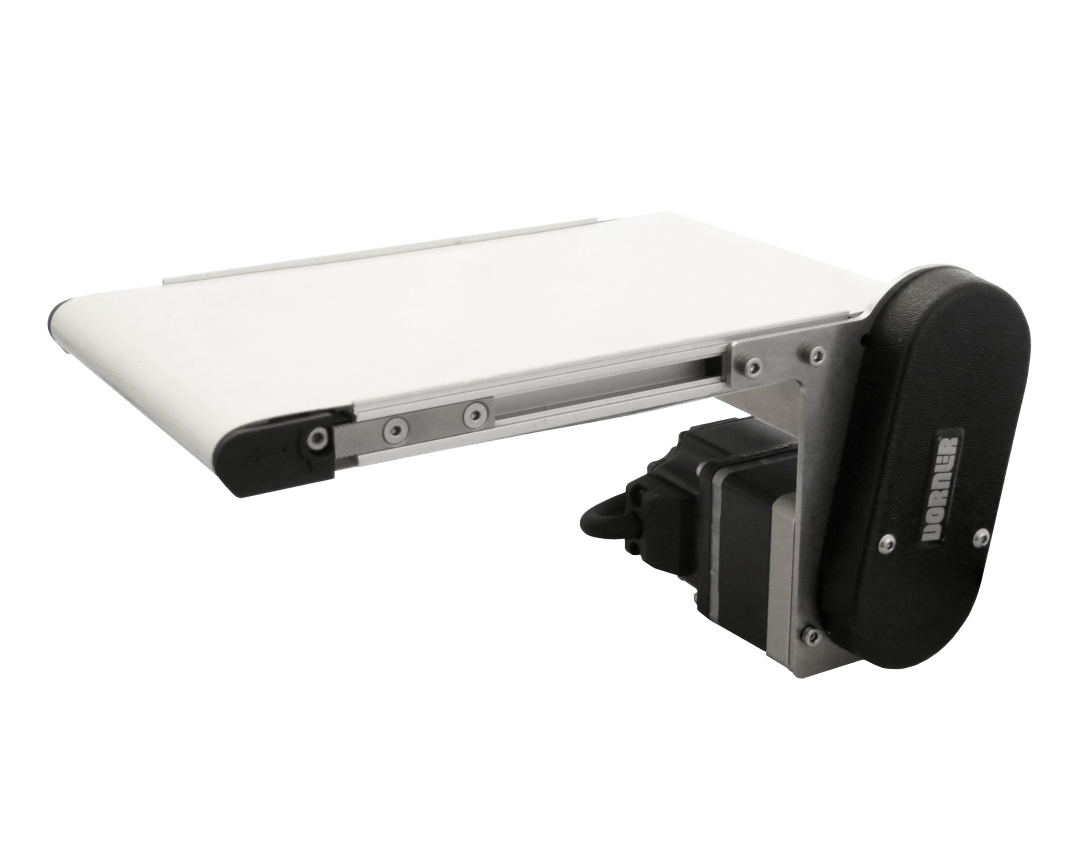

1100 Miniature Belt Conveyors

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of 1X Series

Sizes & Measurements

- Flat Belt End Drive, or Flat Belt Mid Drive

- End Drive – 1″ (25 mm) Diameter Drive Pulley

- Mid Drive – 1.25″ (32 mm) Diameter Center Drive Pulley

- 0.625″ (16 mm) Diameter Idler Pulleys

- 0.31″ (8 mm) Diameter nose bar option for one or both ends

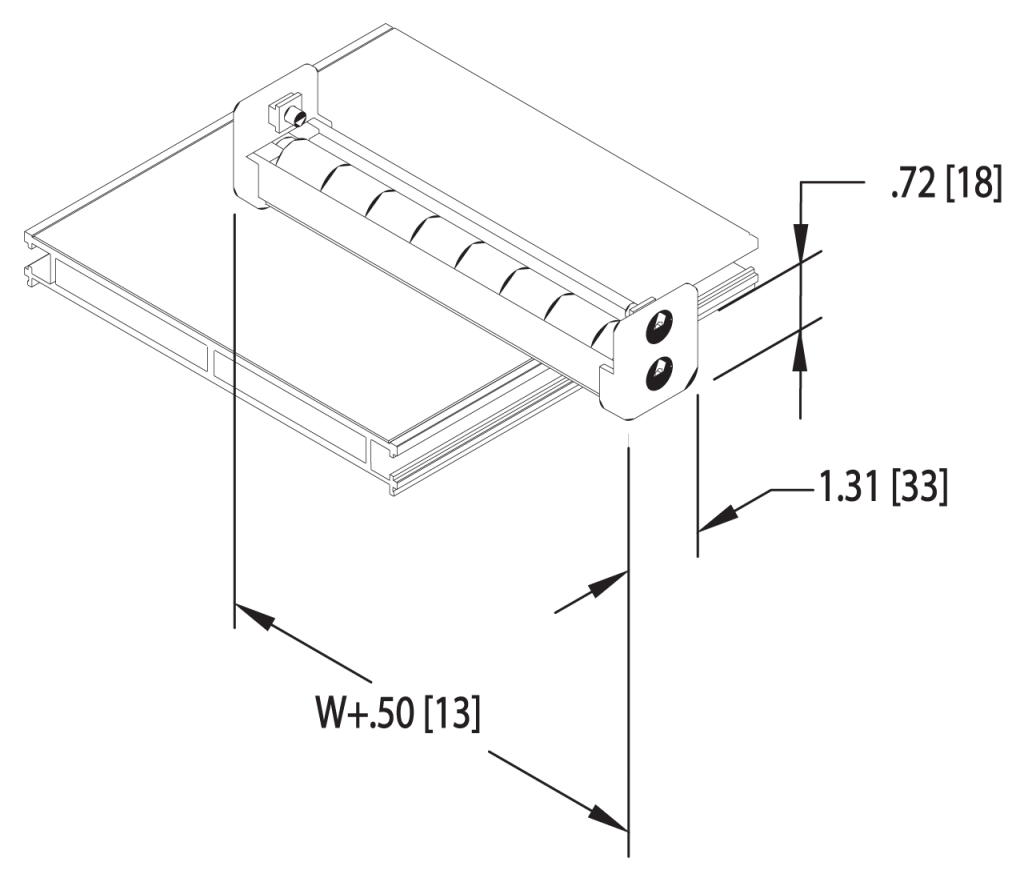

- Belt Widths: 1.75″ (44 mm), 3.75″ (95 mm), 6″ (152 mm), 8″ (203 mm), & 10″ (254 mm)

- Conveyor Lengths: 10.63″ (270 mm) to 72″(1829 mm) in 1/8″ (3 mm) increments

- Loads up to 15 lbs (6.8 kg)

- Belt Speeds up to 80 fpm (21 m/min)

General Applications

- Small or light weight product movement

- Medical

- Pharmaceutical

- Life sciences

Features

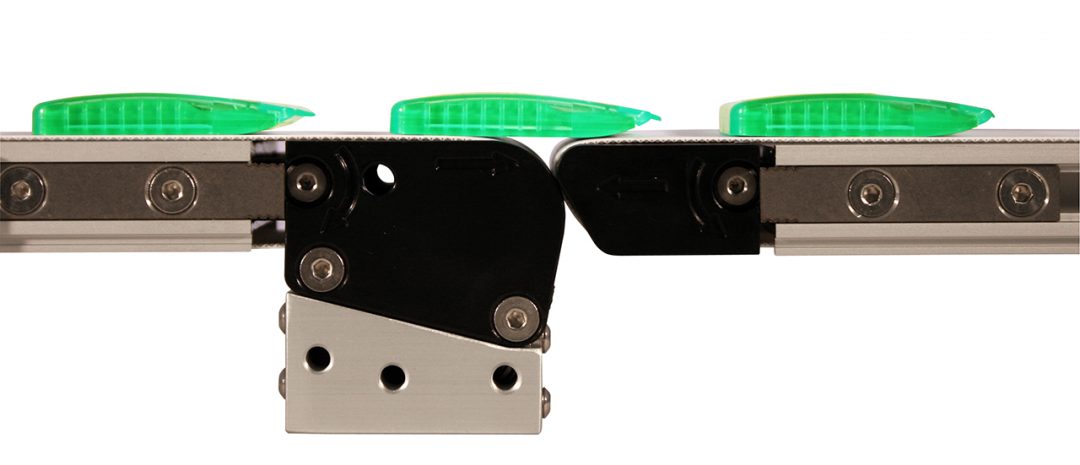

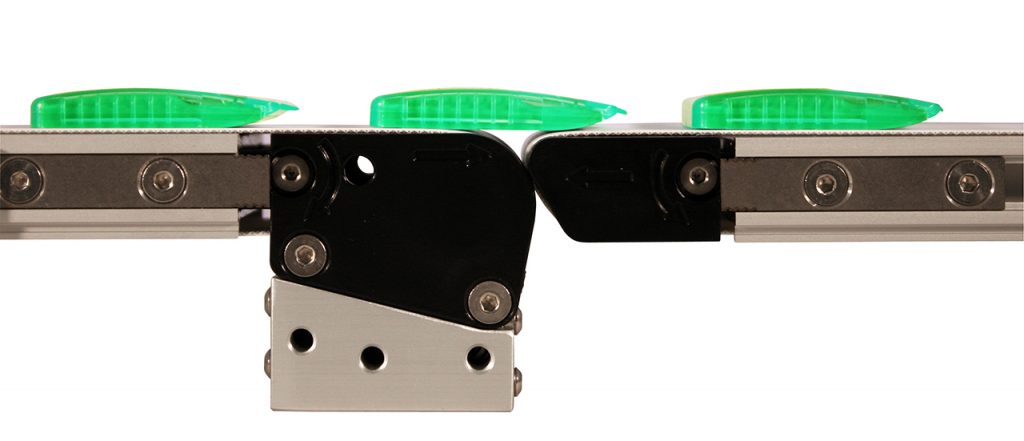

- Pinch Drive Design

- Low belt tension virtually eliminates belt stretch providing maintenance free operation

- Belt is tracked continuously with unique frame design, cams, and pinch drive for consistent performance

- Drive is reversible, providing maximum flexibility in applications

- Two halve design with one fastener per side allows cover to pivot for fast belt change

- T-Slot for flexible mounting

- Spring tensions belt around drive pulley for 180° of wrap

- Low Profile Height – Compact miniature design frees up valuable machine or worker space

- Small Roller Diameter – Optimal size for the handling of small parts and transfer of small parts

- Clean Room Certified – Class 100 certified for use in medical and pharmaceutical clean room applications

- T-Slot – Drop in T-bar for ease and flexibility in mounting automation components or accessories

- Backlit Capability – Backlit conveyor with an LED light is ideal for inspection and quality control

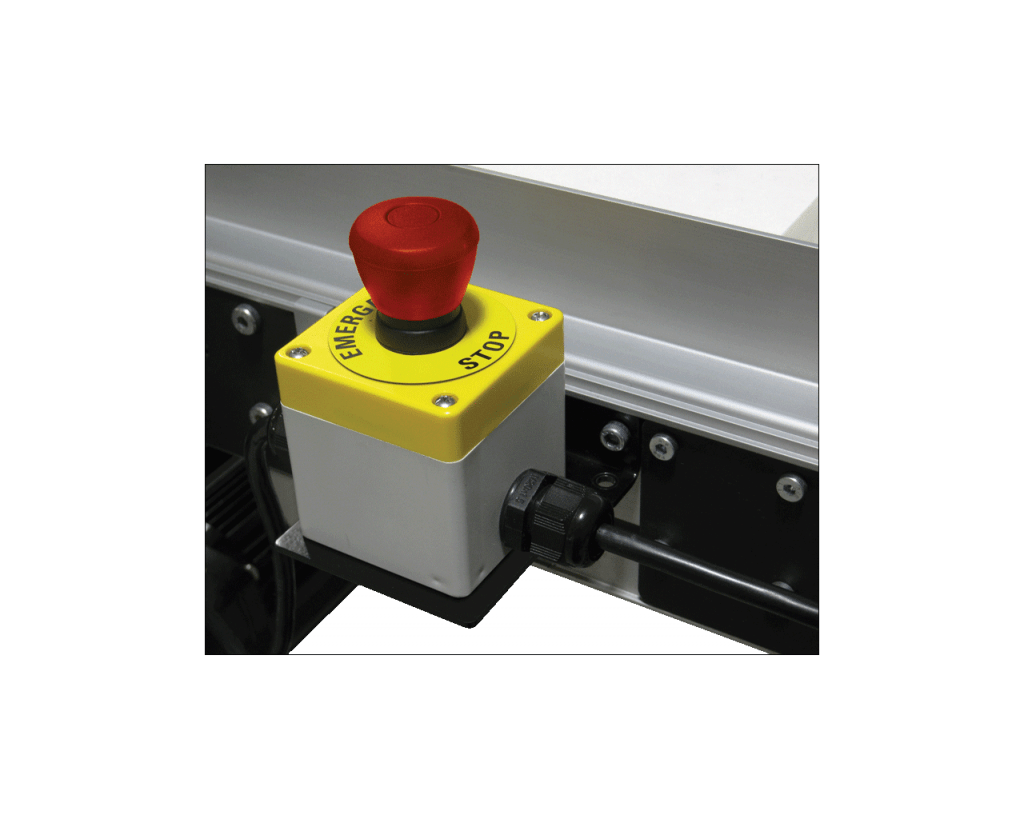

Accessories

Profiles

Belting

Gearmotors

Drive Mount Packages

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| 1100 Series Engineering Manual | 20 | 5.05 MB |

| Literature | Pages | File Size |

| 1100 Series Brochure | 2 | 4.3 MB |

| Backlit Conveyors | 1 | 619 MB |

| Resources | Pages | File Size |

| Miniature Conveyors White Paper | 9 | 494 KB |