- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Industrial and Automation Conveyors

Industrial and automation conveyors are a crucial part of any production facility. Industrial and automation conveyors move parts and product from one place to another during specific steps in the production process. Industrial conveyors are also widely known as industrial conveyor belts, industrial conveyor systems and industrial conveyor belt systems.

Automation conveyors—sometimes referred to as conveyor automation solutions, automated conveyor and sortation systems and automated conveyor belt systems— offer highly accurate product control. Automation conveyors move product at a precise time to an exact location, ensuring that everything is always in the correct phase of the production line. Conveyor systems will improve efficiency, boost accuracy and cut costs. They will also increase workplaces’ safety by reducing the need for lift trucks and other potentially dangerous equipment.

Industrial and Automation Conveyors

Often more standard than automation conveyors, industrial conveyors are behind every stage of the manufacturing process, from production and assembly to inspection and packing. They normally come in two varieties, fabric belted and modular belted. These conveyors help increase efficiency, reduce costs and keep all operations running smoothly.

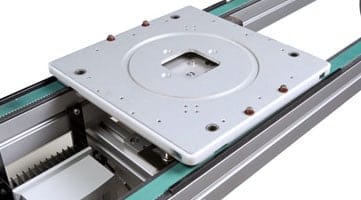

Automation conveyors are a type of conveyor that offers even more precision, especially when moving pallets or larger products. They are typically involved in more automated solutions. Conveyor automation can also be integrated with robots, equipment and workers.

Features and Benefits

Industrial and automation conveyors present businesses with many features and benefits that can be considered in determining the best choice for their applications.

Following are a list of features and benefits:

Features

- Product repositioning conveyor technology

- Variety of belt, roller and other move options for easy line transportation

- Flexibility to grow according to your needs

- Solutions for both small and large products

- Unique indexing and positioning abilities

- Vacuum and backlit conveyors

- Lift gates options

- Leading sorting technologies

Benefits

- Versatile layout flexibility

- Easy to reconfigure and add on to

- Highly accurate positioning and routing

- Improved production line efficiency

Key Industries for Industrial and Automation Conveyors

Industrial conveyor belts are utilized in a range of industries, including the automotive, food processing, packaging, metal working, and pharmaceutical industries. These industrial conveyor belt systems excel in a number of applications such as accumulation, assembly automation, part handling and packaging. These conveyors transport items from boxes, packages and totes to edible products such as fruits and meats.

Automation conveyor belts are also used in many industries, especially those that require flexibility while maintaining precision when moving pallets. Automated systems reduce costs and downtime, all while saving time and resources. Industries that will benefit from automation conveyor belt systems include medical product and device packaging, automotive assembly, and appliance manufacturing.

Get In Touch

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy