Accessories for: AquaGard 7350 and AquaPruf 7400, 7600, 7600 Ultimate and 7600 Vertical.

Guides

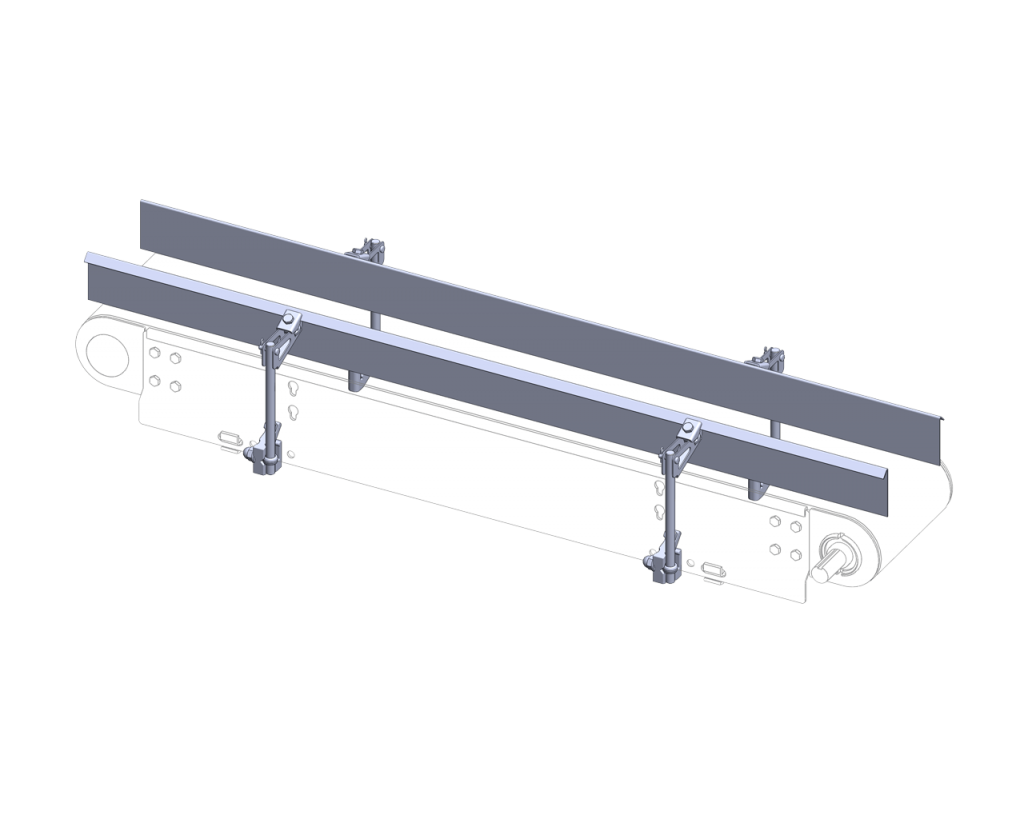

3″ Tall Hinged Guide

- Stainless Steel Hinged guides can be pivoted back to allow easy access to the belt for cleaning.

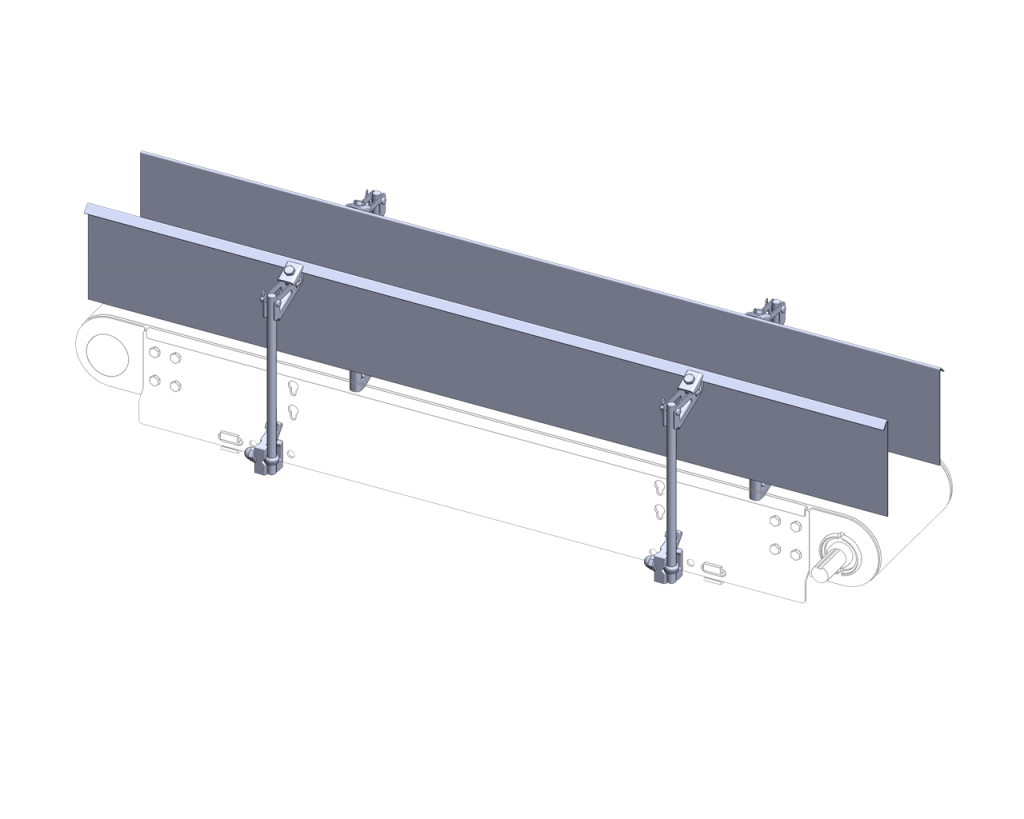

6″ Tall Hinged Guide

- Stainless Steel Hinged guides can be pivoted back to allow easy access to the belt for cleaning.

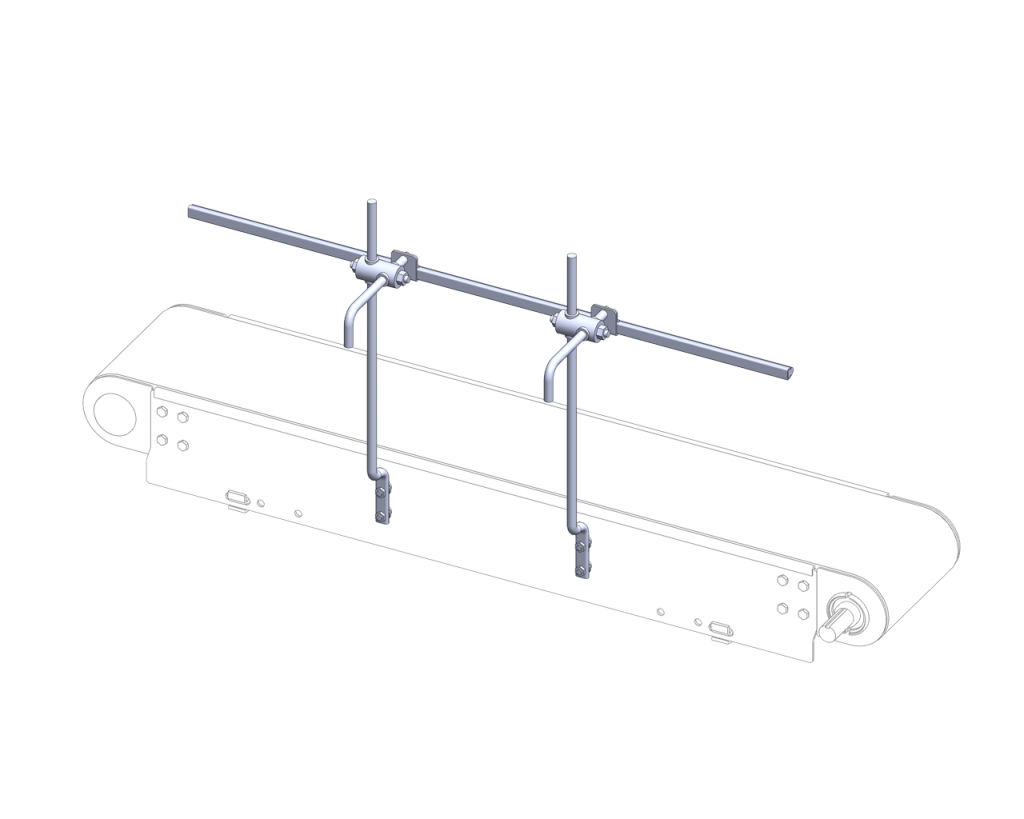

Adjustable Hinged Guide

- Stainless Steel Rod Guide can be adjusted vertically and horizontally using a wrench. These guides are hinged for easy belt access. NOTE: Guiding is sold for each side of the conveyor separately.

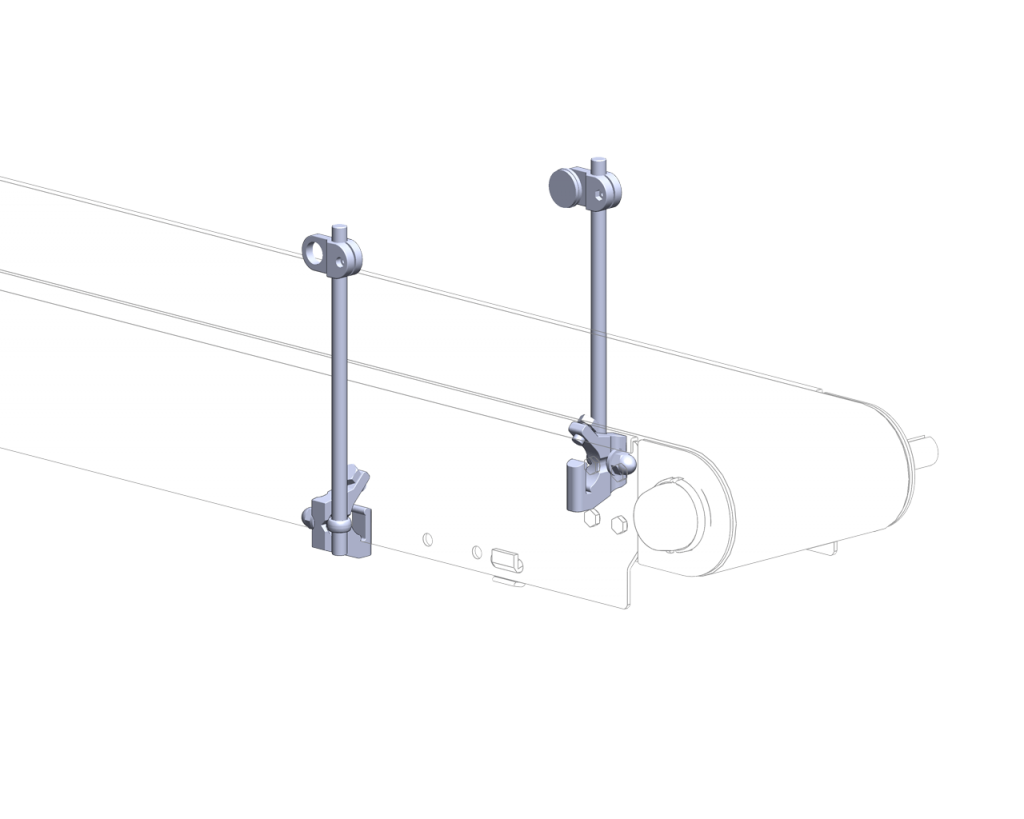

Upper Guide with Vertical Post

- Used for guiding lids and/or tall parts

- Round nose UHMW guide with stainless steel backing

- Equipped with or without tall adjustable height bracket

- Length: 3’ to 10’ in 1’ increments

(2) width adjusting options (standard 5” post, 10” post) - Brackets provided for every 2’ of length

- Available in standard adjustable and tool-less adjustable mount styles

- All brackets and fasteners are stainless steel

Overhead Guide

- For part hold down or cover closing

- Adjustable height and position across width

- Round nose UHMW guide with stainless steel backing

- Lengths: 3’ to 10’ in 1” increments

- Horizontal Brackets provided for every 2’ of length

- Available in standard adjustable and tool-less adjustable mount styles

- All brackets and fasteners are stainless steel

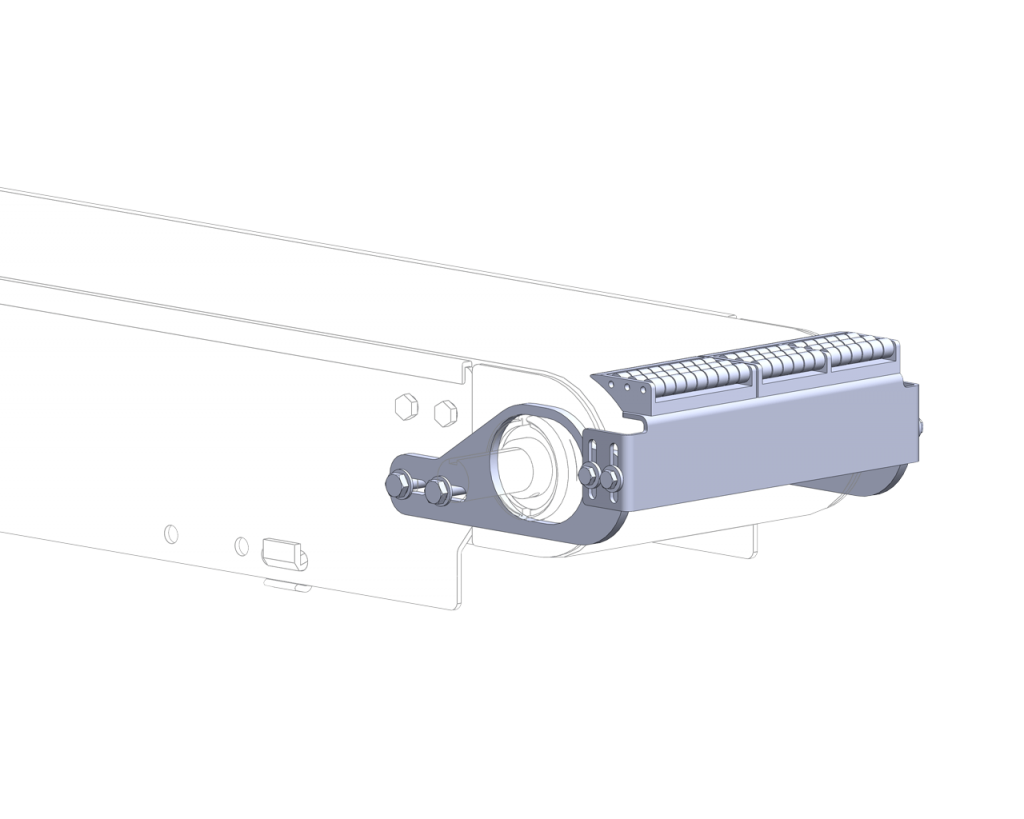

Transfers

Powered Transfer Specifications

- FDA approved 1/2” diameter self lubricated nose bar bushings

- Positive drive FDA approved urethane belting

- 300 series stainless steel / anodized aluminum construction

- Plated corrosion resistant bearings

- Used on infeed and exit tail

- For infeed tail : Needs conveyor to be ordered with output shaft tail

- For exit tail : Needs conveyor to be ordered with dual output shaft tail

- Can be purchased as a conveyor only

- Does not include mounting brackets or series drive

- Includes output shaft only

Conveyor Specifications:

- Conveyor Width: 4” wide to 36” wide in 2” increments

- Conveyor Length: Adds less than 8” to conveyor length

- Conveyor Speed: Up to 175 ft/min

Features & Benefits

- 1/2” diameter nose rollers for small part transfer

- Adjustable height and distance to main roller for fine tuning the product transfer

- High speed positive drive conveyor belts to ensure consistent speed

- Maintains product speed through transfer for gapping and pacing

- Located at drive and/or idler end of main conveyor

- Compatible with both curve and straight conveyors

- Compatible with all end drive tails and drive mount packages

- Made of corrosion resistant materials for wipe down or occasional wash down

- Series driven from main roller for minimal install requirements

Series Drive Speed Options:

- Same Speed

- Speed Up by 1.6 : 1

- Speed Down by 1.25 : 1

Powered Transfer for Non-Dorner Conveyors

Roller Transfer

- 4” wide to 52” wide

- Includes 0.43” diameter rollers mounted in transfer plate

- Adjustable mounting to fine tune small parts transfer

- All brackets and fasteners are stainless steel

Mounting & Hardware

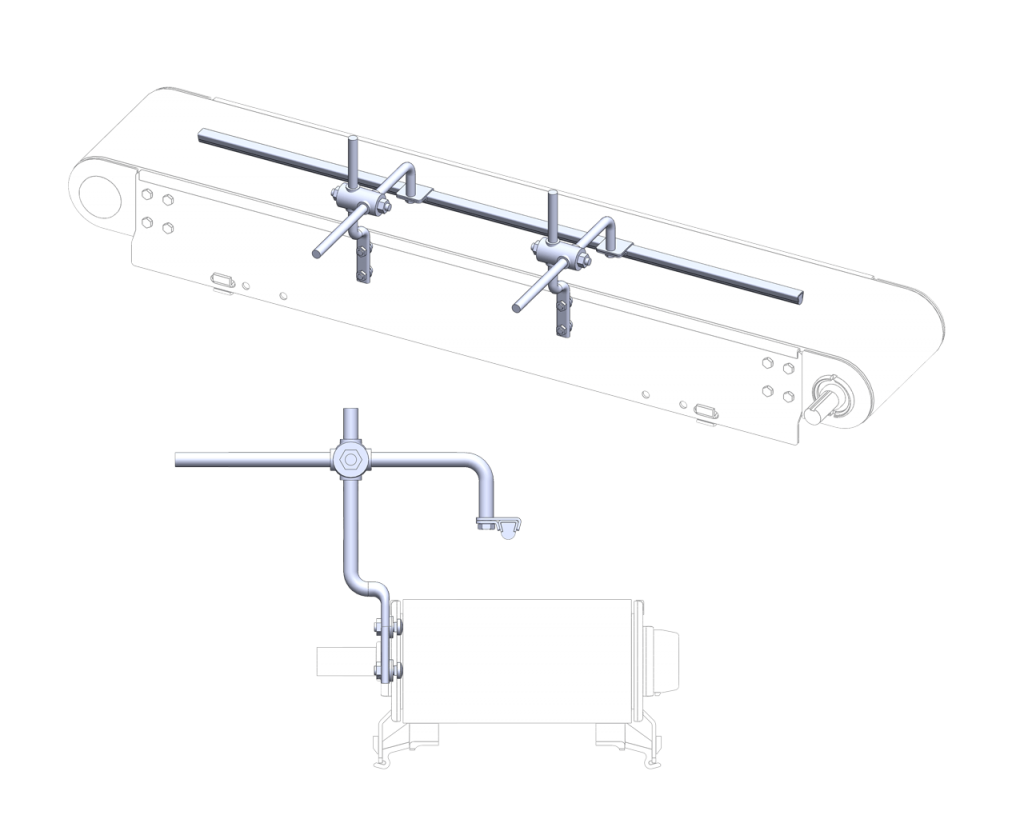

Accessory Mounting Bars

- Used for mounting adjustable devices such as photoeyes and sensors

- Can be mounted directly to frame or in combination with guide brackets

- 2 Versions:

- 3’ bar used to mount to 24” hole pattern in frames

- 1’ L shape used to mount at tail ends

- Compatible with Value Guide blocks (VG-021-02)

- All brackets and fasteners are stainless steel

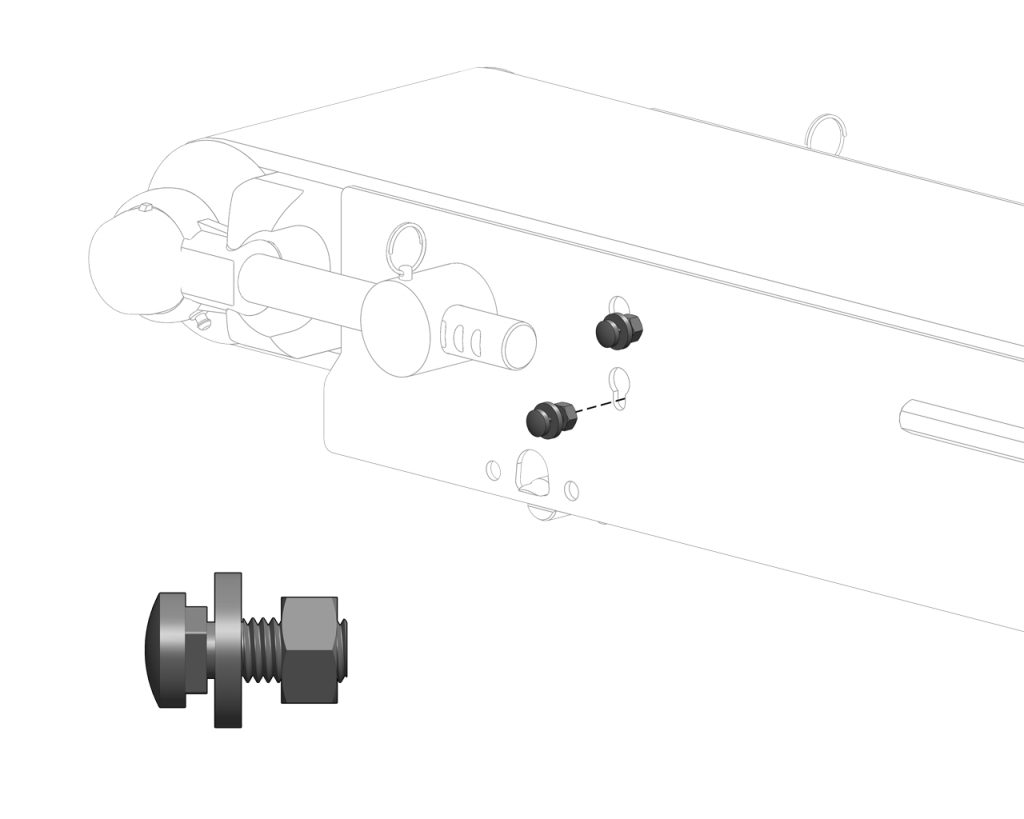

Keyslot Bolts

- Stainless steel mounting hardware

- M8-1.25 Male mounting stud

- Used with Dorner key-slot system

- Eliminates the need to access the inside of the frame

- Package of 10 pieces

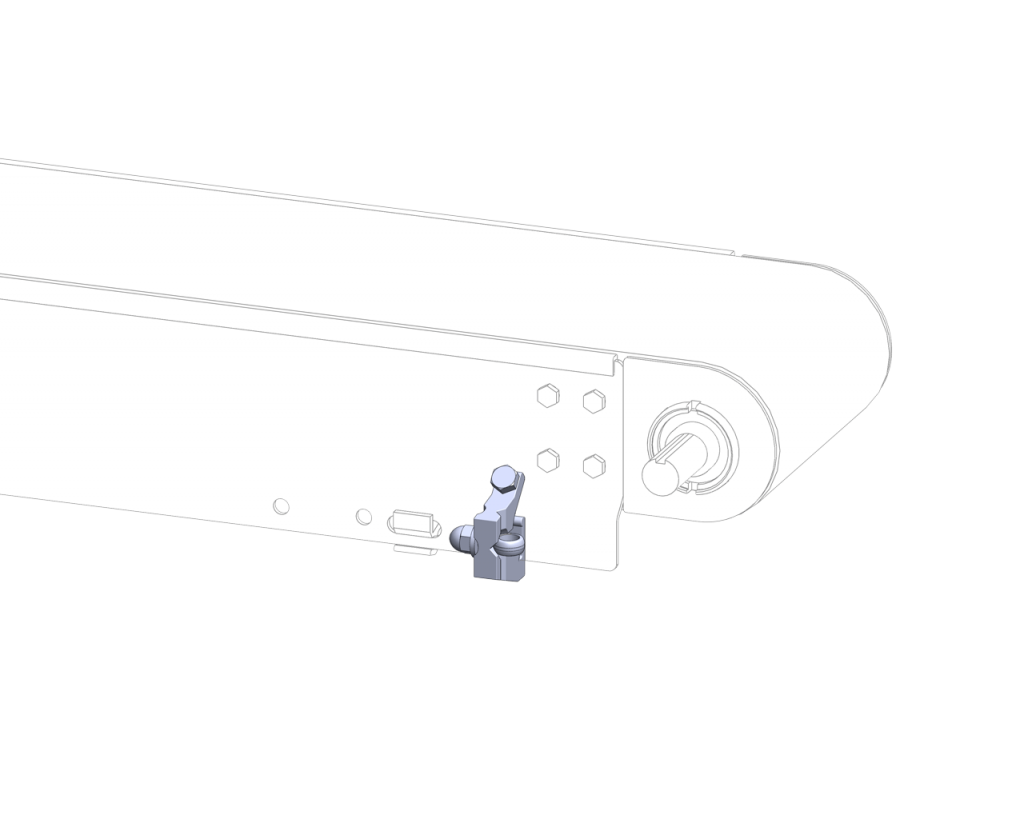

Accessory Mounting Bracket

- Mount accessory items to the AquaPruf and AquaGard conveyors

- Mount accessories without frame modifications

- Clamps ½” diameter shaft for ease of accessory mounting

- All components are 300 series stainless steel

- Adjustable along the length of the conveyor

- All adjustment screws located outside the food zone

Includes

- All adjustment screws located outside the food zone

- Clamp ring for ½” shaft with stainless acorn nut (½” shaft not included)

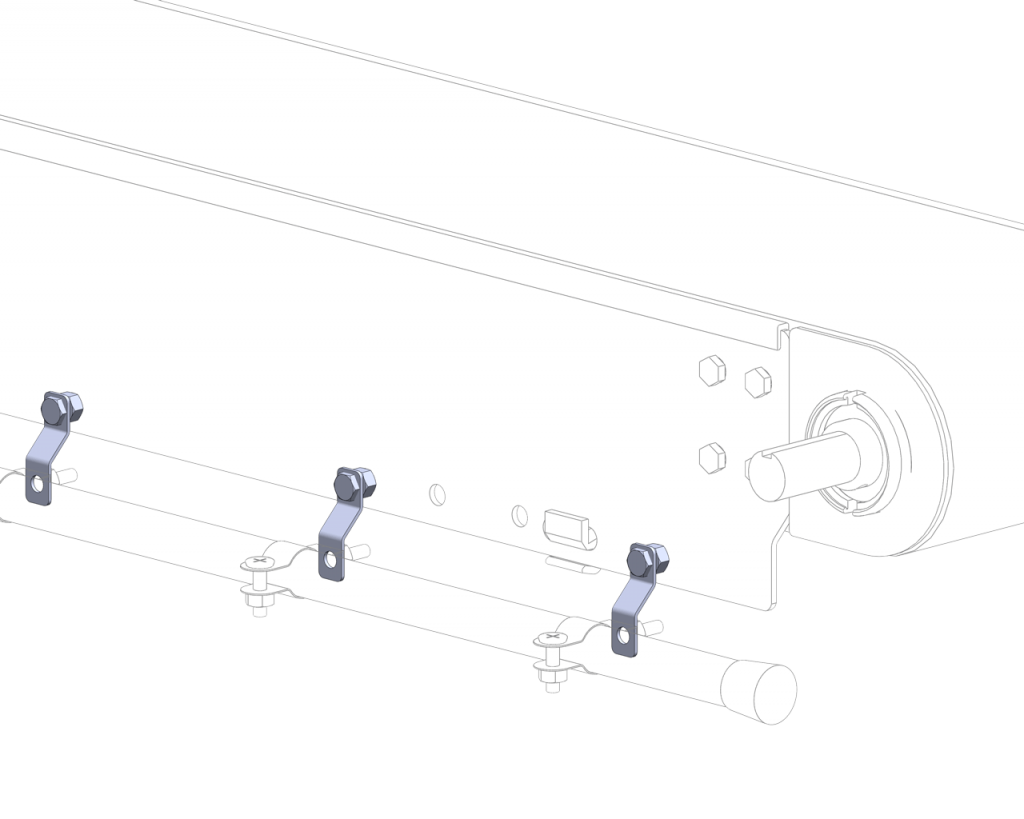

Electrical / Air Mounting Clips

Electrical / Air Mounting Clips

- Light weight mounting clip for wire clips, conduit clicks, wire tie mounts, etc.

- Mounts directly to M8 guide bolts and/or lower frame lip

- May be mounted to inside of frame or outside of frame

- Offset to clear mounting screws

- Package of 10 pieces

- All brackets and fasteners are stainless steel

Photo Eye Kits

Select from a variety of photo eyes and mounting kits.

- Mount photo eyes to the AquaPruf and AquaGard conveyors

- Attach bracket or accessories without frame modifications

- All components are 300 series stainless steel

- Adjustable along the length of the conveyor

- All adjustment screws located outside the food zone

- Fits any 18mm barrel or nose mount photo eye

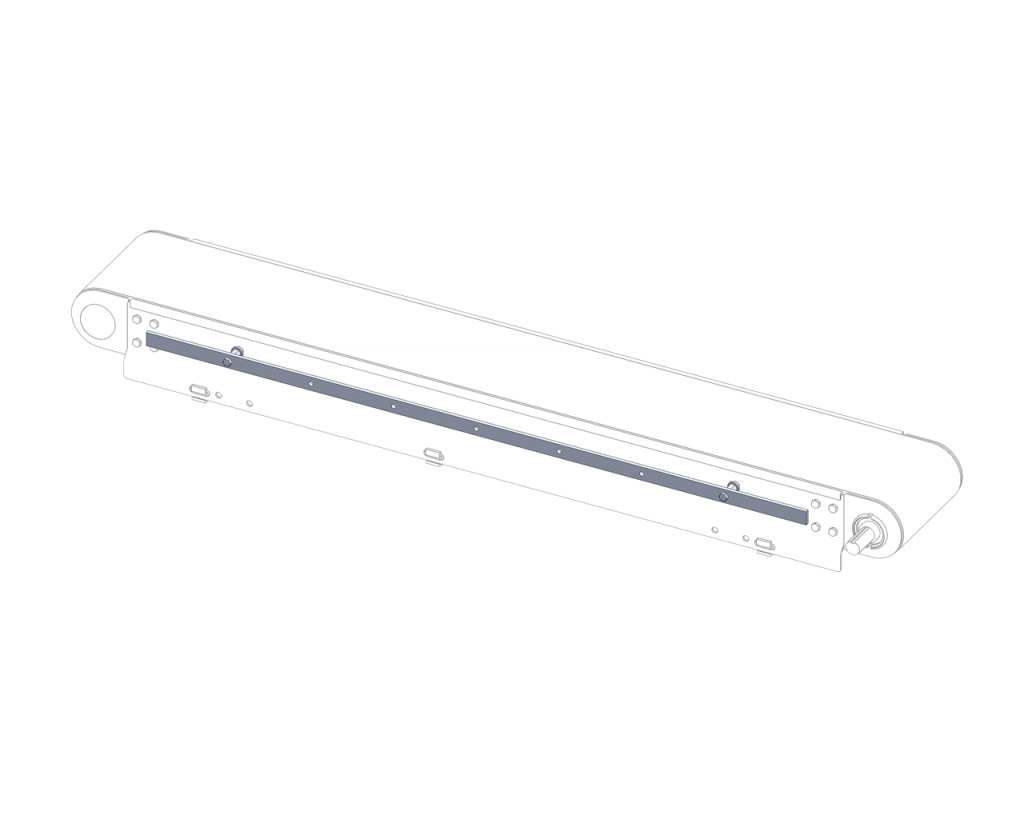

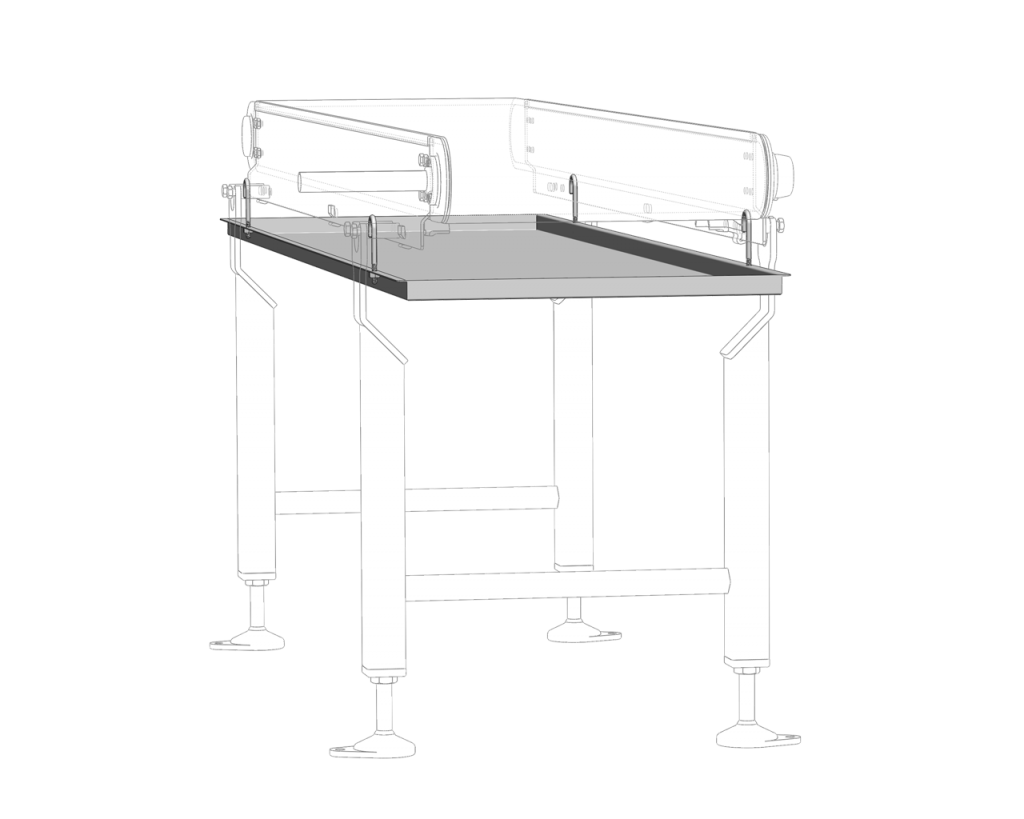

Drip Pans

Specifications

- Widths: 6” (152 mm) to 60” (1,524 mm) available in 2” increments

- Lengths: 24” (610 mm) to 999” (25,375mm) available in 1” increments maximum section lengths of 118” (2,997mm)

Features

- Catch pans for all AquaPruf and AquaGard Conveyors

- Tool-less hook design for fast removal and rapid cleaning

- Provides a 2” window for clean-out access without removal

- All pans equipped with a 1” containment lip on all sides

- All components are 300 series stainless steel

- All adjustment screws located outside the food zone

- Adjustable along the length of the conveyor

- Contact factory for additional options

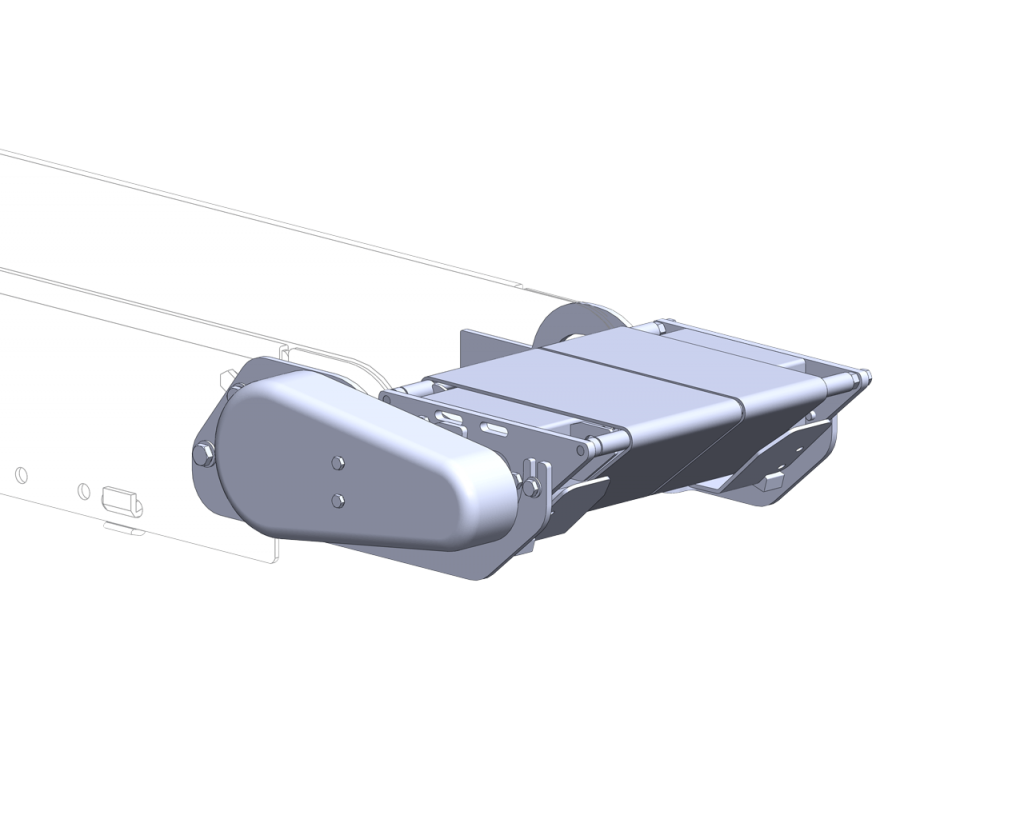

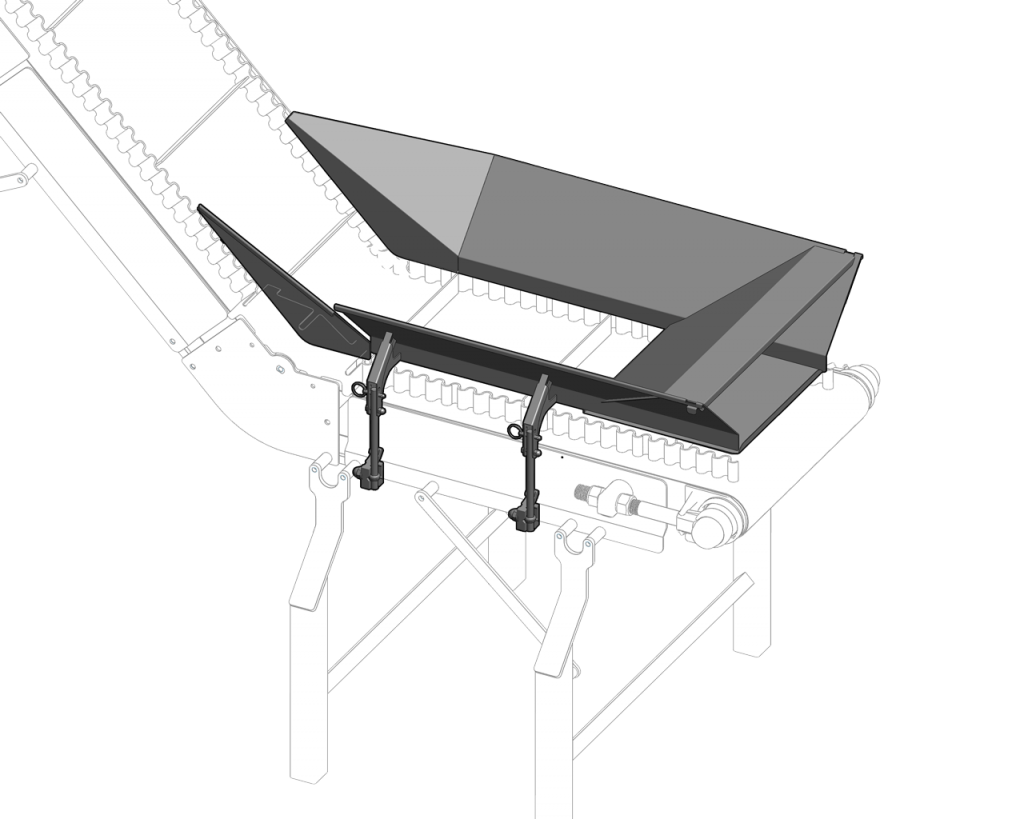

Infeed Chute

Specifications

- Widths: 6” (152 mm) to 24” (610 mm) available in 2” increments

- Lengths: 24” (610 mm) to 72” (1,829 mm) available in 1” increments

- Angles: 5° to 60° in 5° increments

Features

- Bulk handling options for all AquaPruf and AquaGard conveyors

- Chute/Hopper mounts to conveyors without any modifications

- Tool-less hinged design for quick access to the conveyor for rapid cleaning

- All components are 300 series stainless steel

- Adjustable along the length of the conveyor

- All adjustment screws located outside the food zone

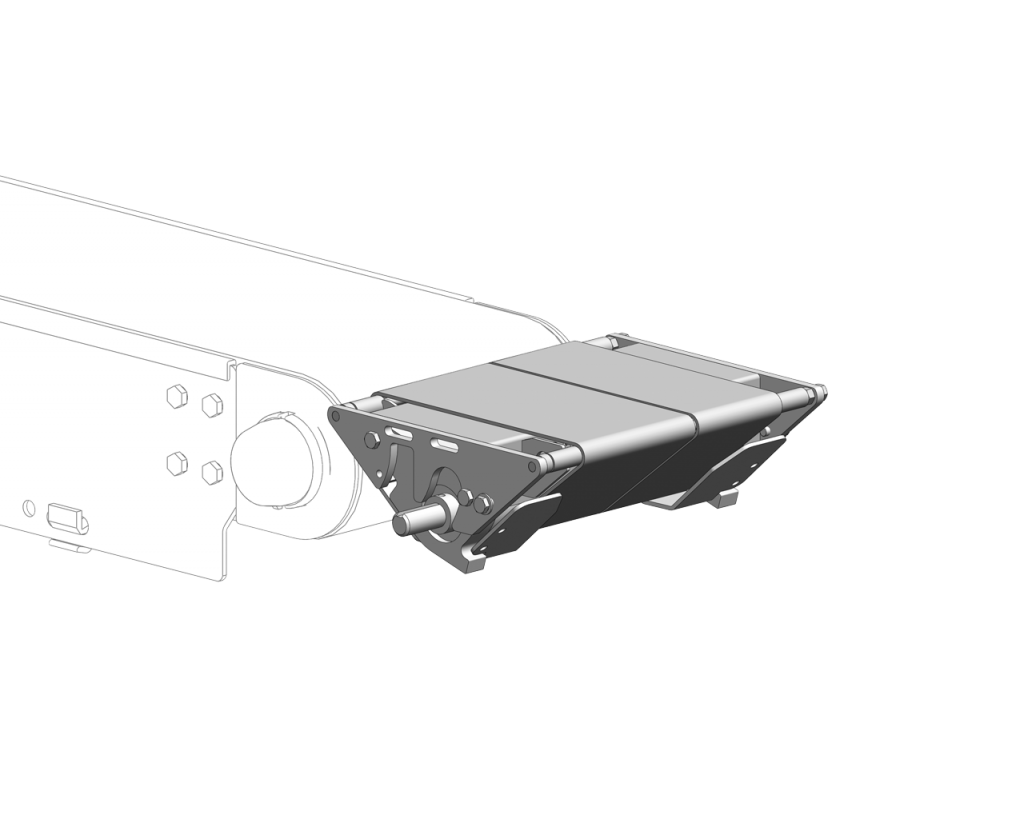

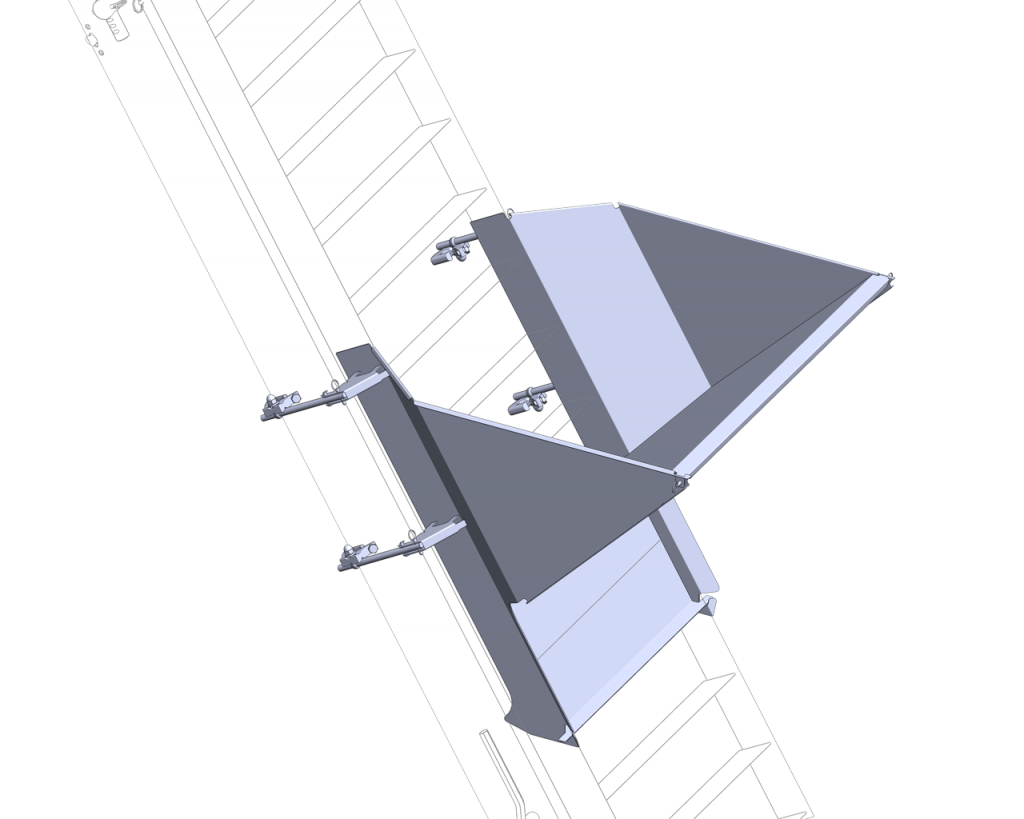

Angled Hopper

Features

- Bulk handling options for all AquaPruf and AquaGard conveyors

- Chute/Hopper mounts to conveyors without any modifications

- Tool-less hinged design for quick access to the conveyor for rapid cleaning

- All components are 300 series stainless steel

- Adjustable along the length of the conveyor

- All adjustment screws located outside the food zone

Specifications

- Widths: 6” (152 mm) to 24” (610 mm) available in 2” increments

- Lengths: 24” (610 mm) to 72” (1,829 mm) available in 1” increments

- Angles: 5° to 60° in 5° increments