AquaPruf 7400 Ultimate Conveyors

Contact Us

Conveyor specialists are ready to help you find the right solution

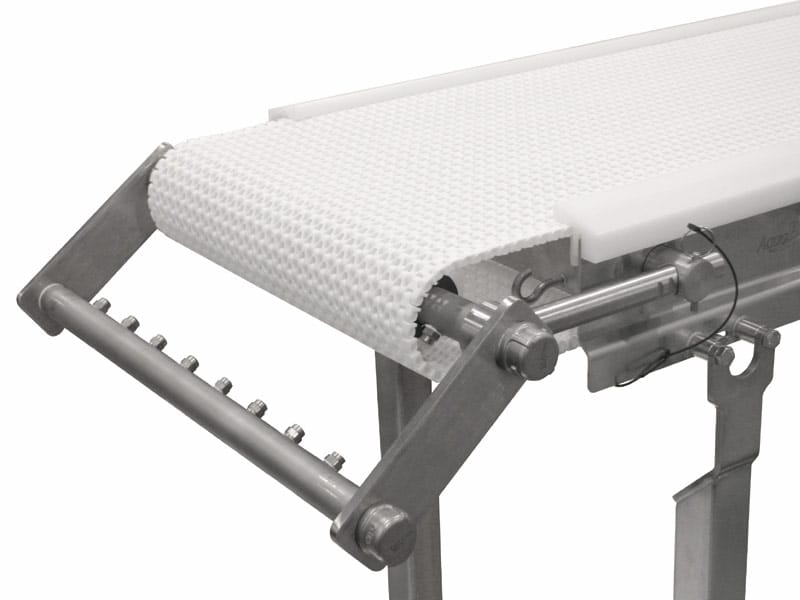

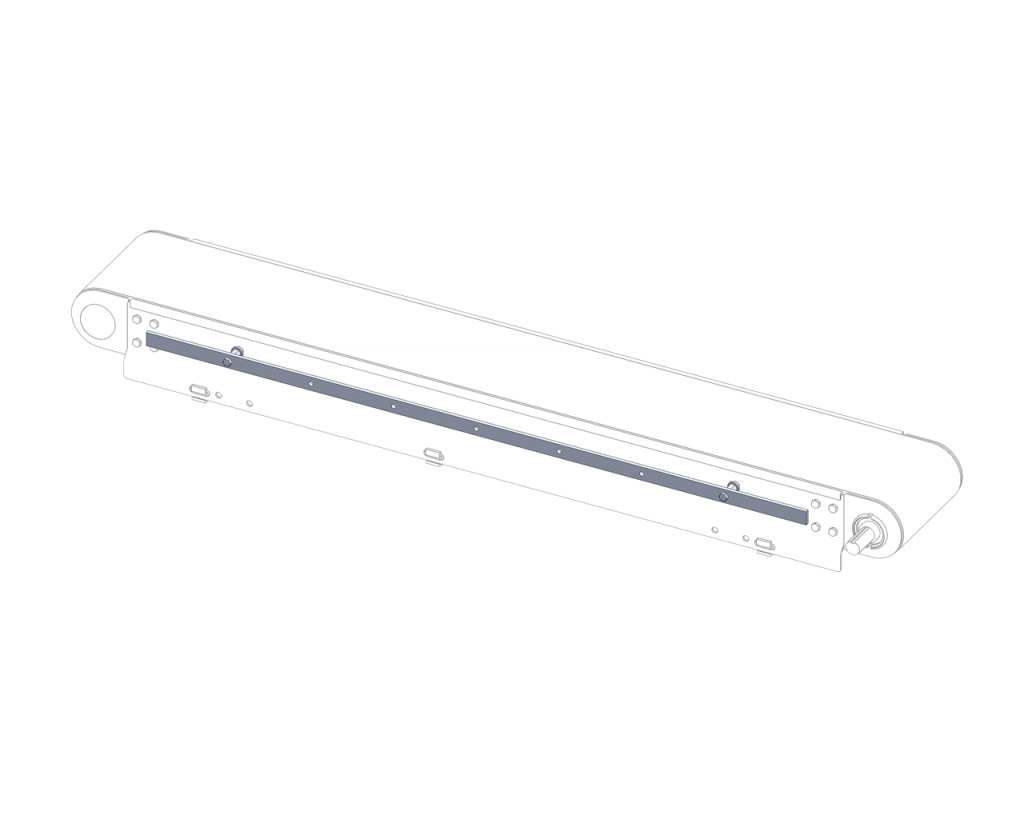

7400 Sanitary Modular Belt – Highest Level Of Sanitation

The Ultimate Series has been engineered for Fast & Effective Sanitation in the most demanding environments. These include facilities where food safety is crucial such as: RTE foods, raw protein (meat – poultry – fish), dairy and other environments with high pressure sanitation requirements.

Benefits of 7400 Ultimate AquaPruf Conveyor:

- Frame is designed with no horizontal surfaces for optimum cleaning. Conveyors over 10′ long consist of multiple sections which are bolted together (can be welded together on site).

- Bearings are mounted in cast stainless steel housing for maximum performance in washdown environments

- Solid UHMW wear strips are easily lifted out of the frame without tools to minimize cleaning time.

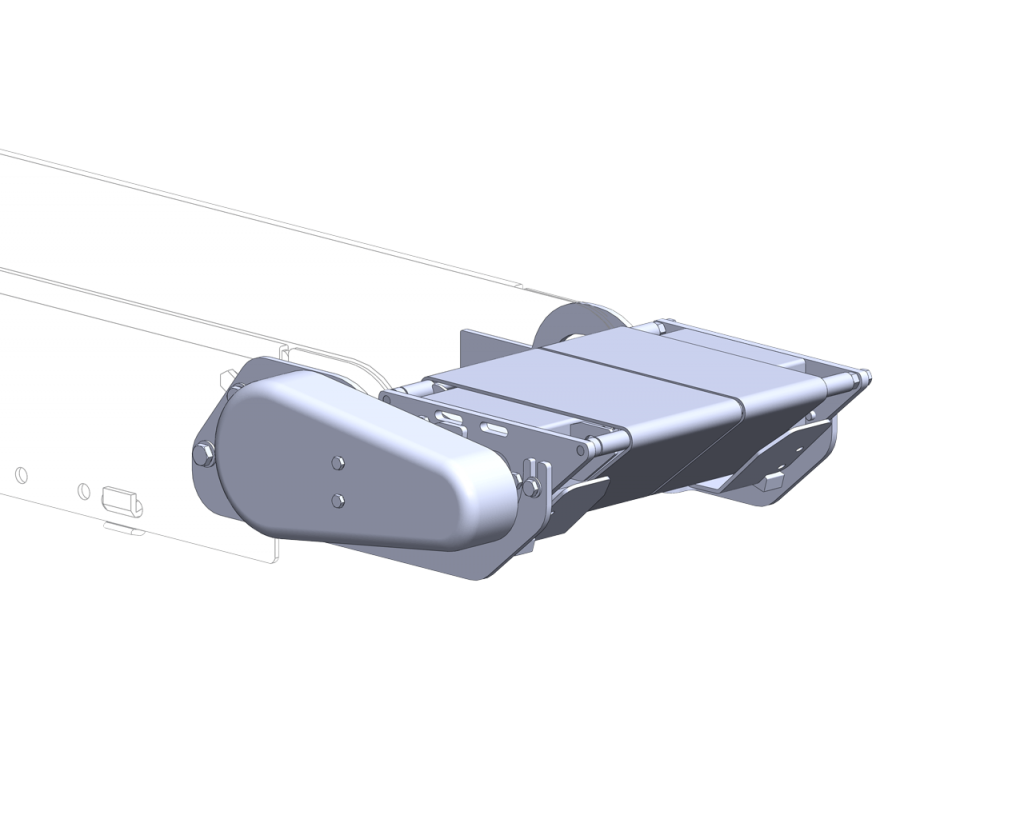

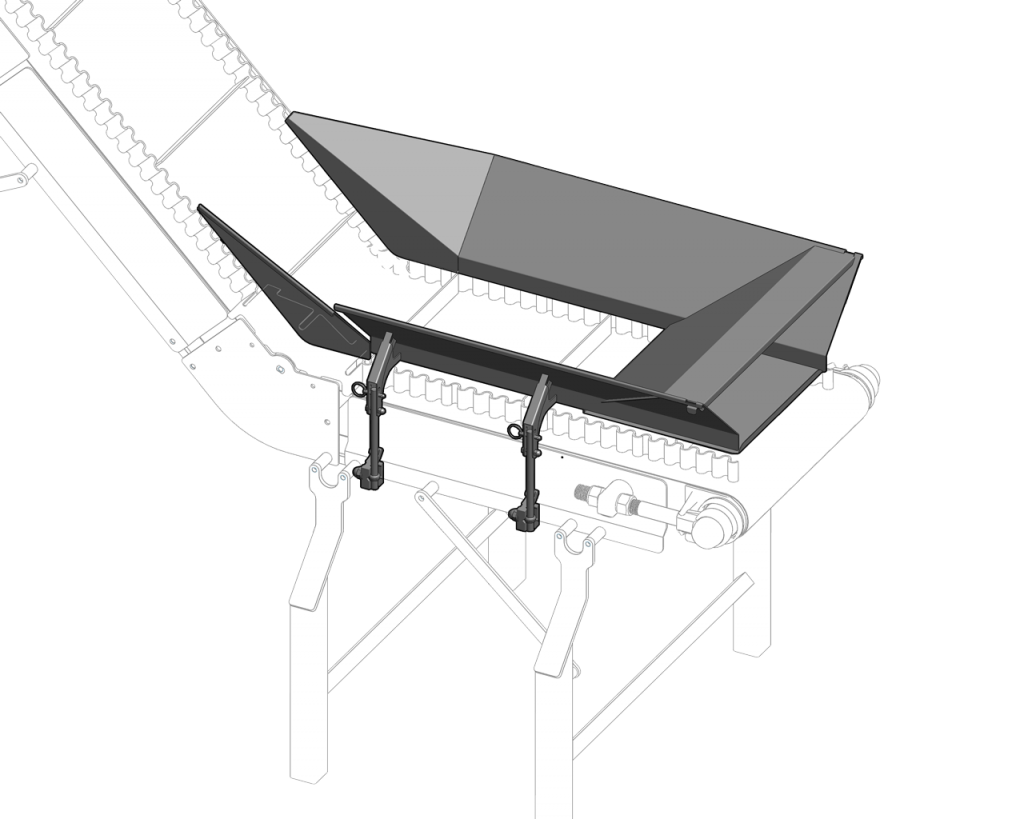

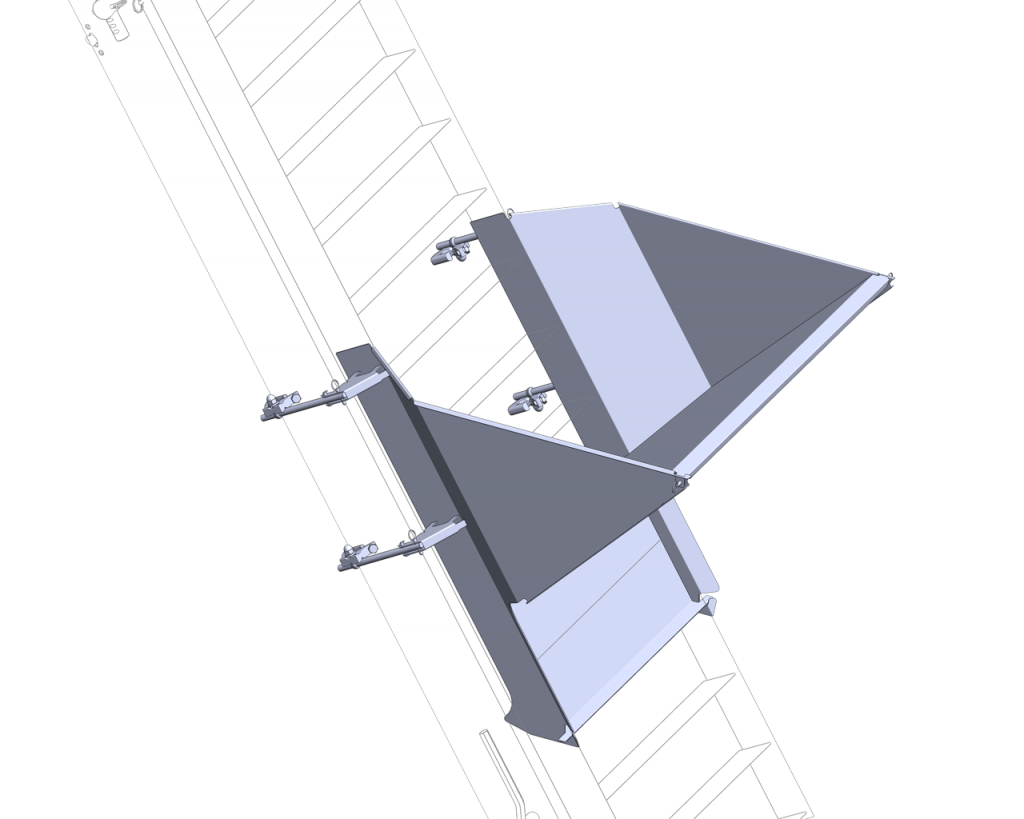

- the tool-less tip up pulley allows conveyor end to be lifted easily for quick access to inside of conveyor for cleaning.

- Open Belt Tracking Flanges and solid UHMW idler pucks create access to pulleys.

- Conveyor is designed to withstand high pressure (100-1,500 psi) spray and chlorinated solutions.

- The return belt supports are segmented plastic slide blocks and are easily removed without tools for effective cleaning.

- Drive sprockets are located on 1.5″ square stainless steel shaft without fasteners to provide optimum drive strength and cleanability.

- Nose bar idler ends (optional) are constructed of machined UHMW bar to provide a 1.5″ diameter transfer.

- The nose bar drive configuration (optional) are available to allow spraying the inside of the conveyor without lifting the belt.

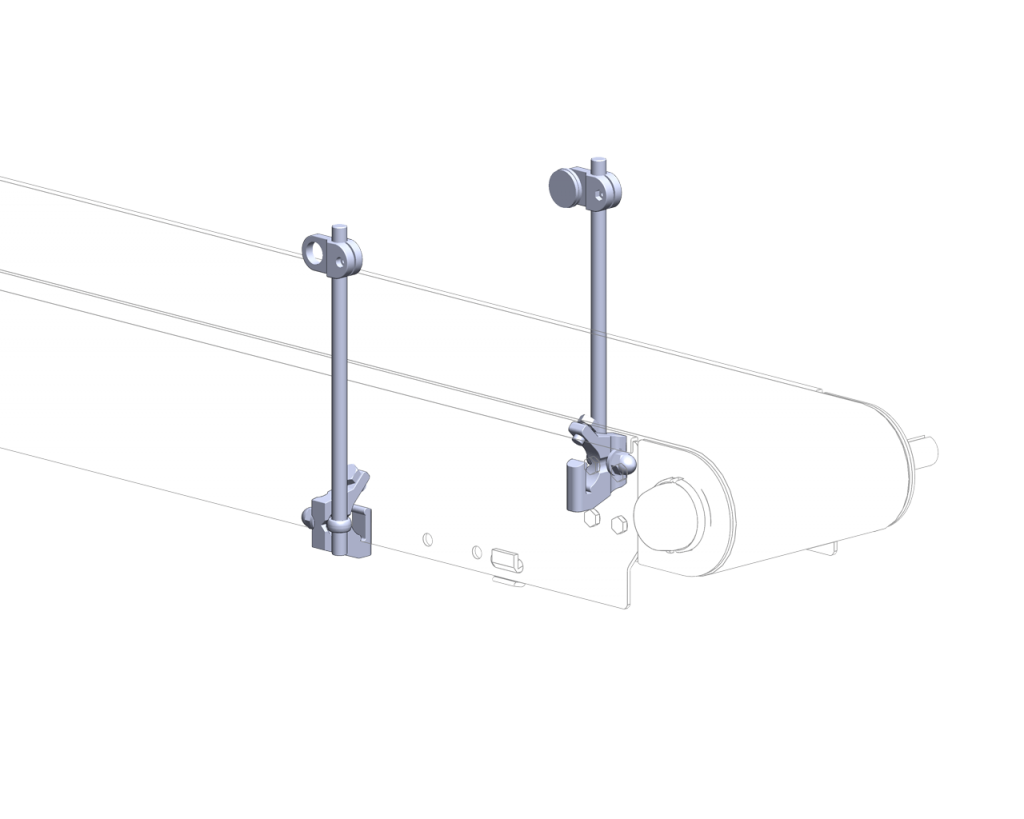

- Belt lifters (optional) raise the belt from the wear strips by simply pulling an external lever for fast access and effective cleaning

- TIG welded stand offs keep fasteners out of the food zone.

Specifications

- Load: 20 lbs/square-foot of belt

- Belt Widths: 6″ to 36″

- Lengths: 36″ to 999″

- Belt Speed: 233 ft/min maximum

- UHMW Wear strip bed plate

- Continuous TIG welded 304 stainless steel frame

- #4 Polish on all frame surfaces

- Bearing material is 400 stainless steel

- Bearing lubricant is H1 type FDA lubricant

- USDA Approved belting and plastic components

- Meets USDA & AMI design specifications

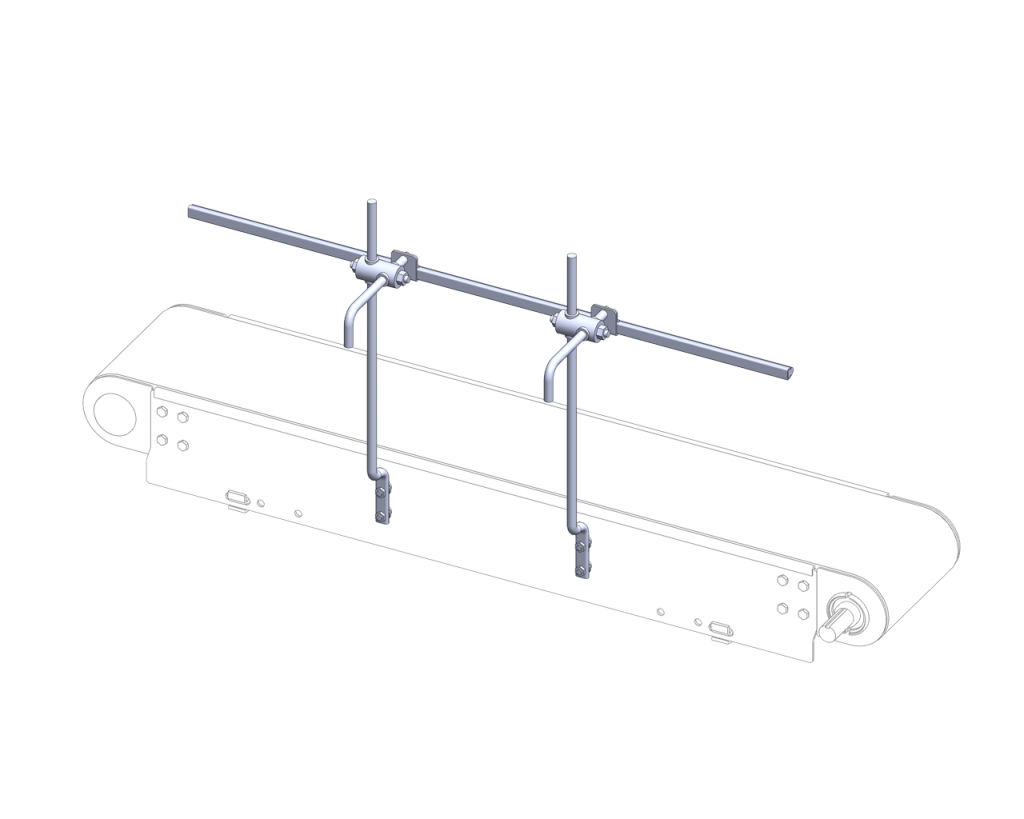

Accessories

Profiles

Belting

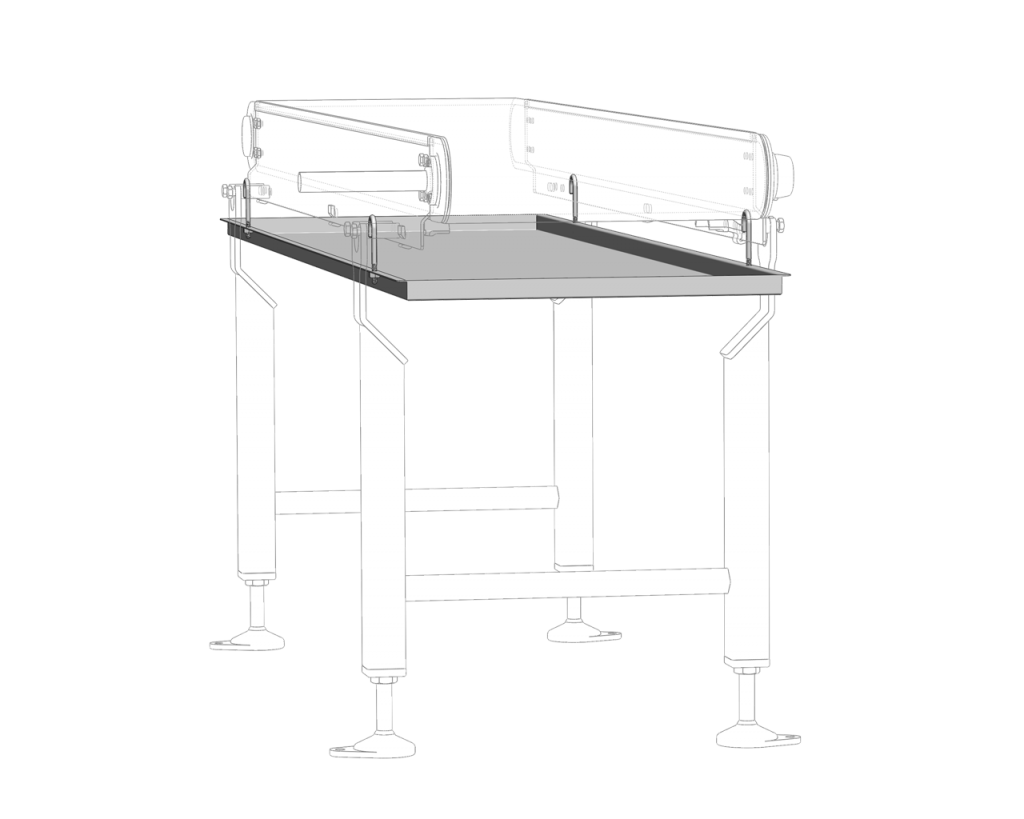

Support Stands

Gearmotors

Drive Mount Packages

Manuals & Literature

| Engineering Manuals | Pages | File Size |

| Literature | Pages | File Size |

| AquaPruf Brochure | 6 | 3.15 MB |

| Sanitary Conveyors Brochure | 6 | 5.97 MB |