- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

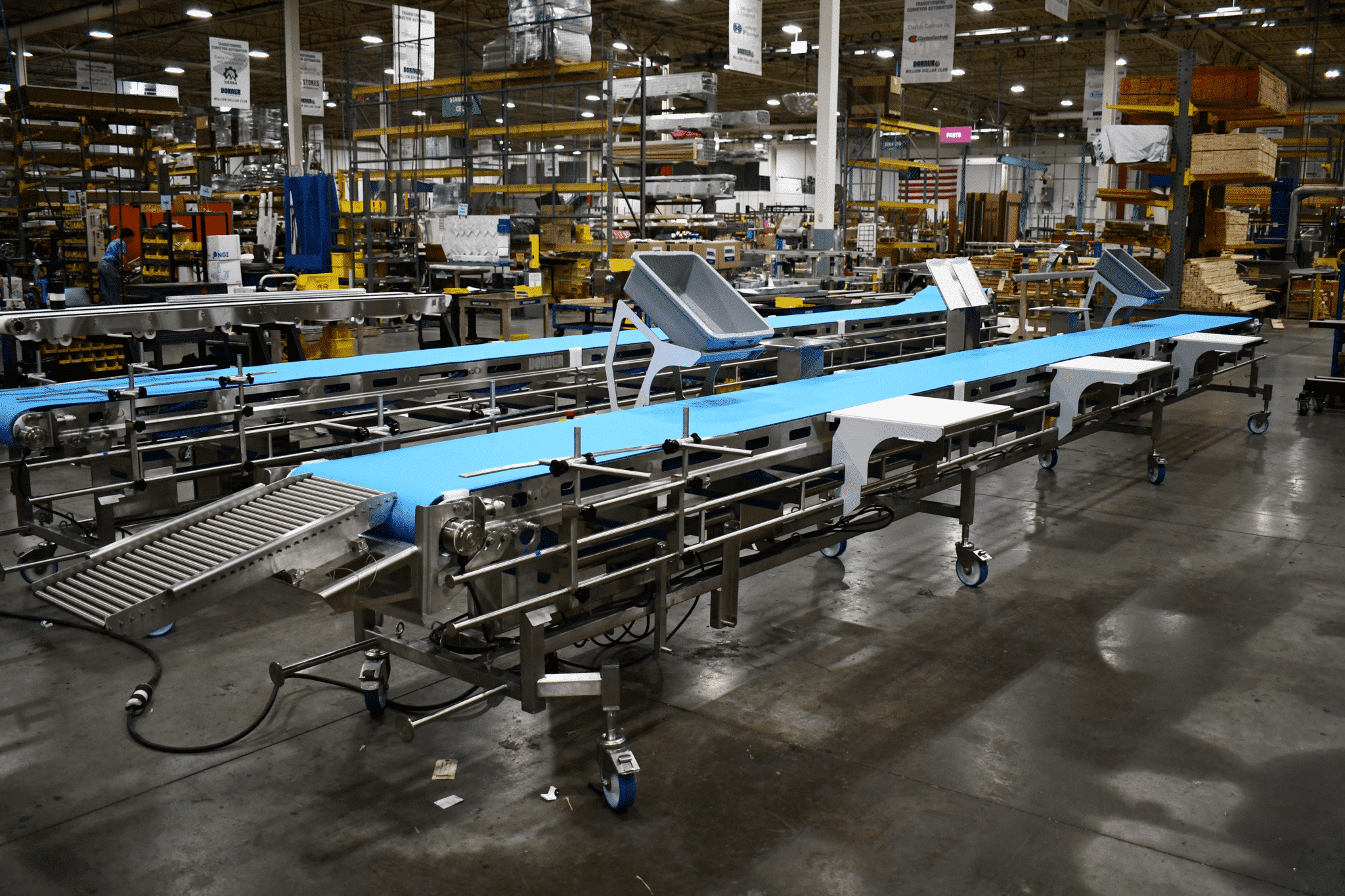

Ready-to-Eat Conveyor System Case Study

This case study showcases Dorner’s recent project for a grocery store chain that was looking for a solution to help them produce sandwiches and other ready-to-eat meals.

The Challenge

Many food manufacturers are continuously challenged to increase their product offerings to meet customer demand while still increasing profits. This grocery store needed to produce multiple types of ready-to-eat sandwiches and salads that required a high level of sanitation to combat cross-contamination, with the flexibility to alter the stations quickly when a different product variation is needed.

Line Changover

Time is of the essence in any manufacturing facility and when utilizing the single conveyance system for multiple product lines that have different assembly instructions, it can be a great challenge to keep production running at the desired pace.

Sanitary Level

Moving raw food products on conveyors is always a challenging task when it comes to properly mitigating the risk of cross-contamination and bacterial growth. This coupled with the line changeover requirements creates the need for an easy solution to clean all elements of the conveyor.

The Consultation

Dorner’s Engineered Solutions Group paired engineers Ryan Johnson and Paul Mirkes to the project for this complex conveyance project. The consultation process involved meeting with the client to discuss their requirements and determine how to best utilize Dorner’s wide breadth of products. Moving into the design stage, it was clear that flexibility and hygiene were the two most critical aspects of achieving the client’s goals. Dorner’s wide product offering, coupled with a team of engineers who provide innovative solutions to challenging applications, made Dorner the ideal conveyance partner for this client.

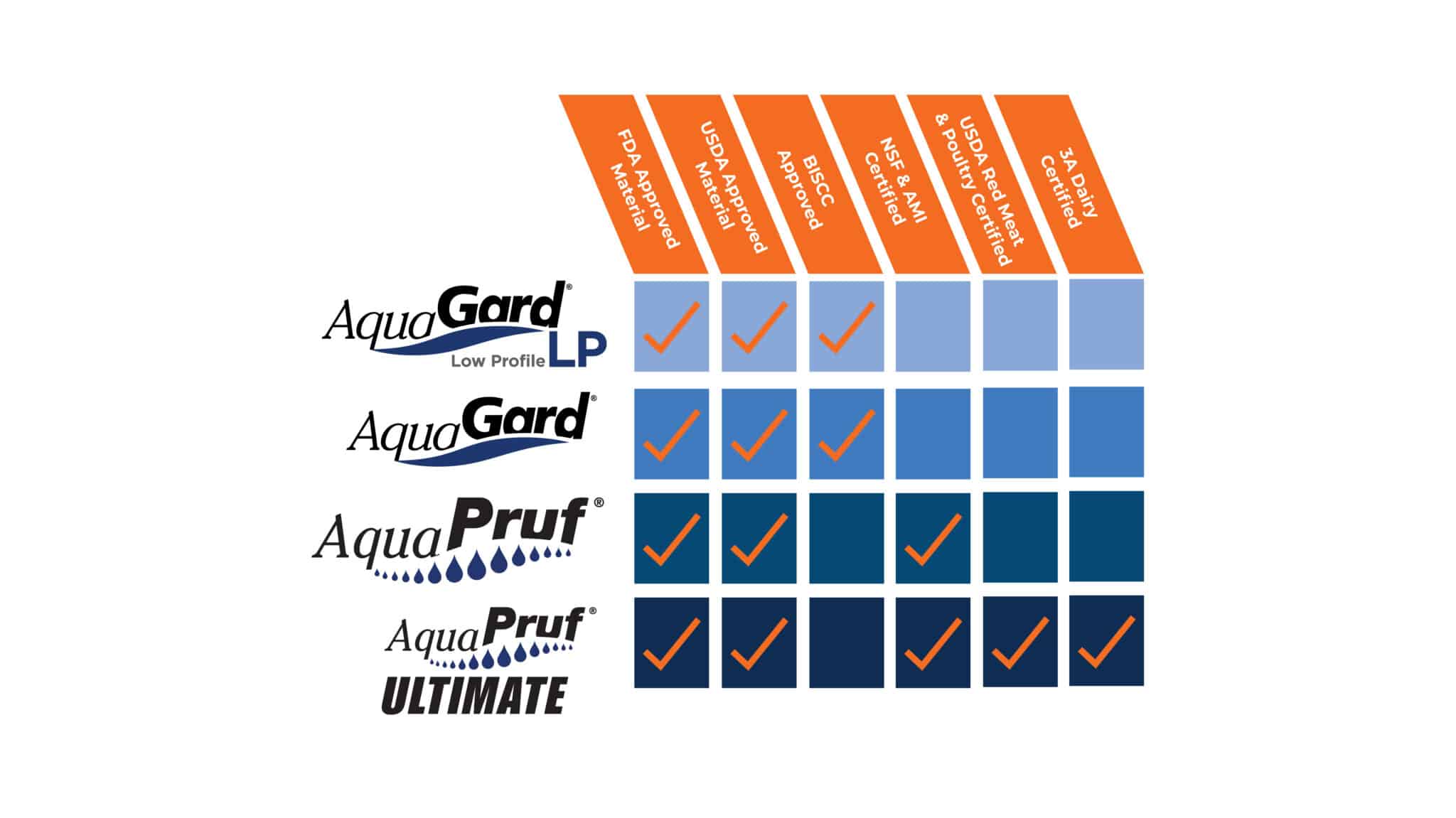

Sanitary Conveyor Options

Accessories

When preparing raw food products, preventing contamination and maintaining the quality of the product is always a top priority. For this application, it was clear that the AquaPruf Ultimate series would give the grocery store the confidence that their new conveyor system could be quickly and easily sanitized to ensure product safety while keeping up with production goals.

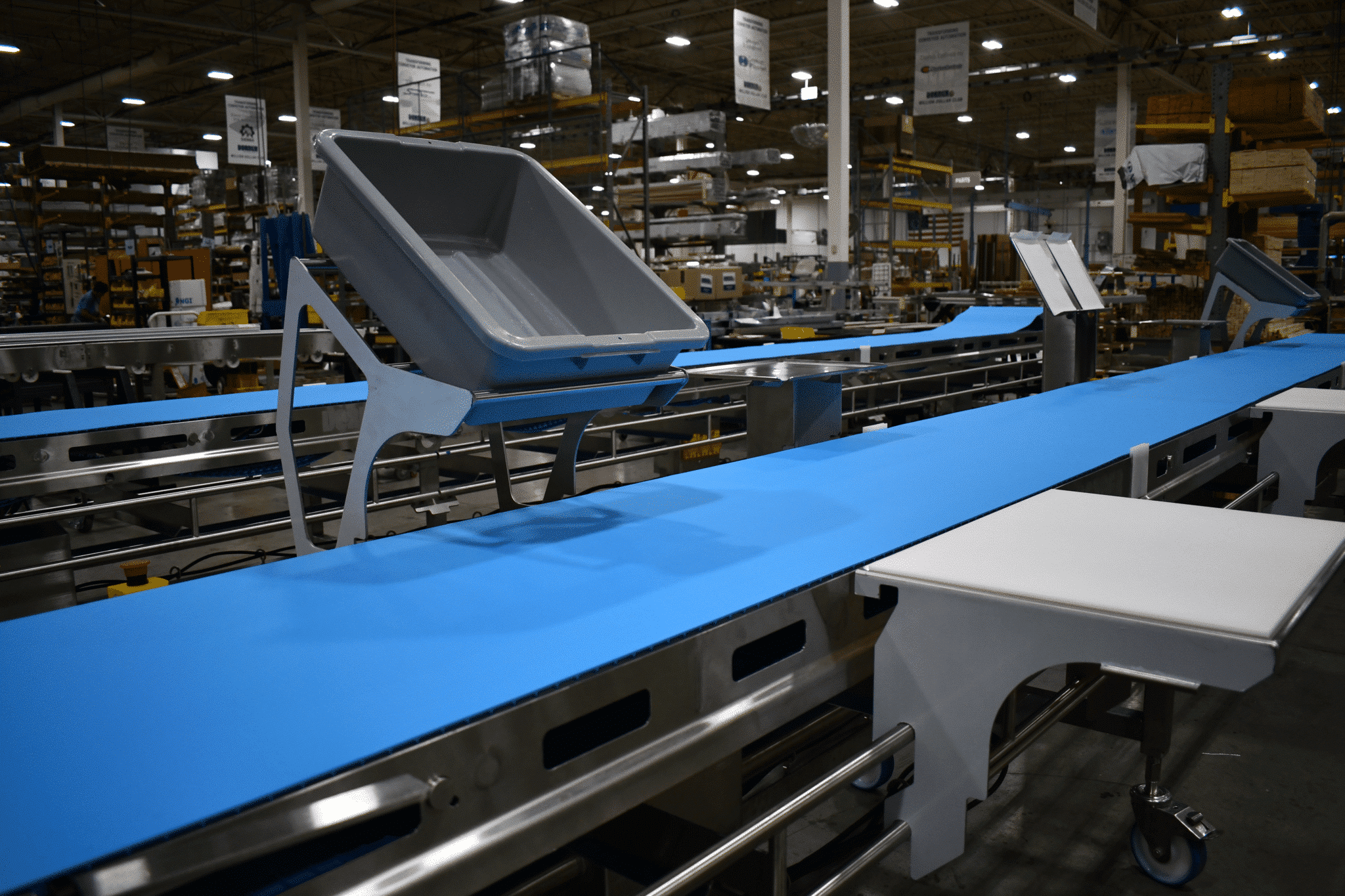

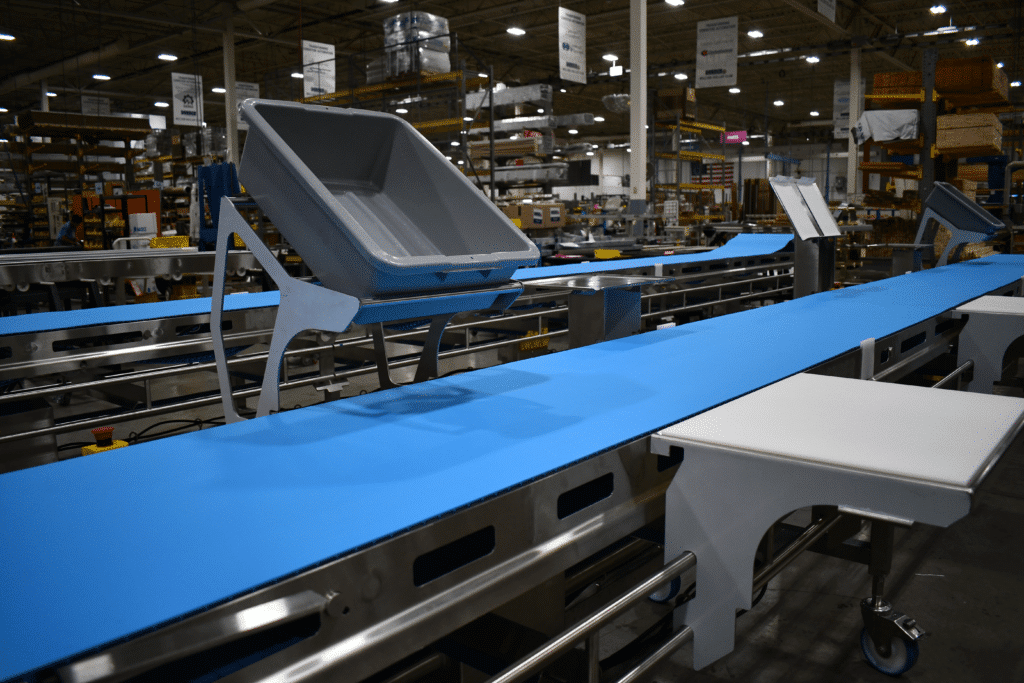

With multiple products with varying ingredients being produced on a single line, every aspect of the system needed to be adjustable. The client required a conveyor system that could adapt to fluctuations in the number of staff working at the conveyor, the positioning of each workstation, and the need for a continuous supply of ingredients. This required a flexible solution with accessories that could be easily moved and interchanged throughout a shift.

The Solution

After taking all of the key requirements for hygiene and flexibility into consideration, Dorner’s Engineered-To-Order team designed a unique AquaPruf Ultimate conveyor that provides the client with the ability to increase production throughput while maintaining a high sanitation standard.

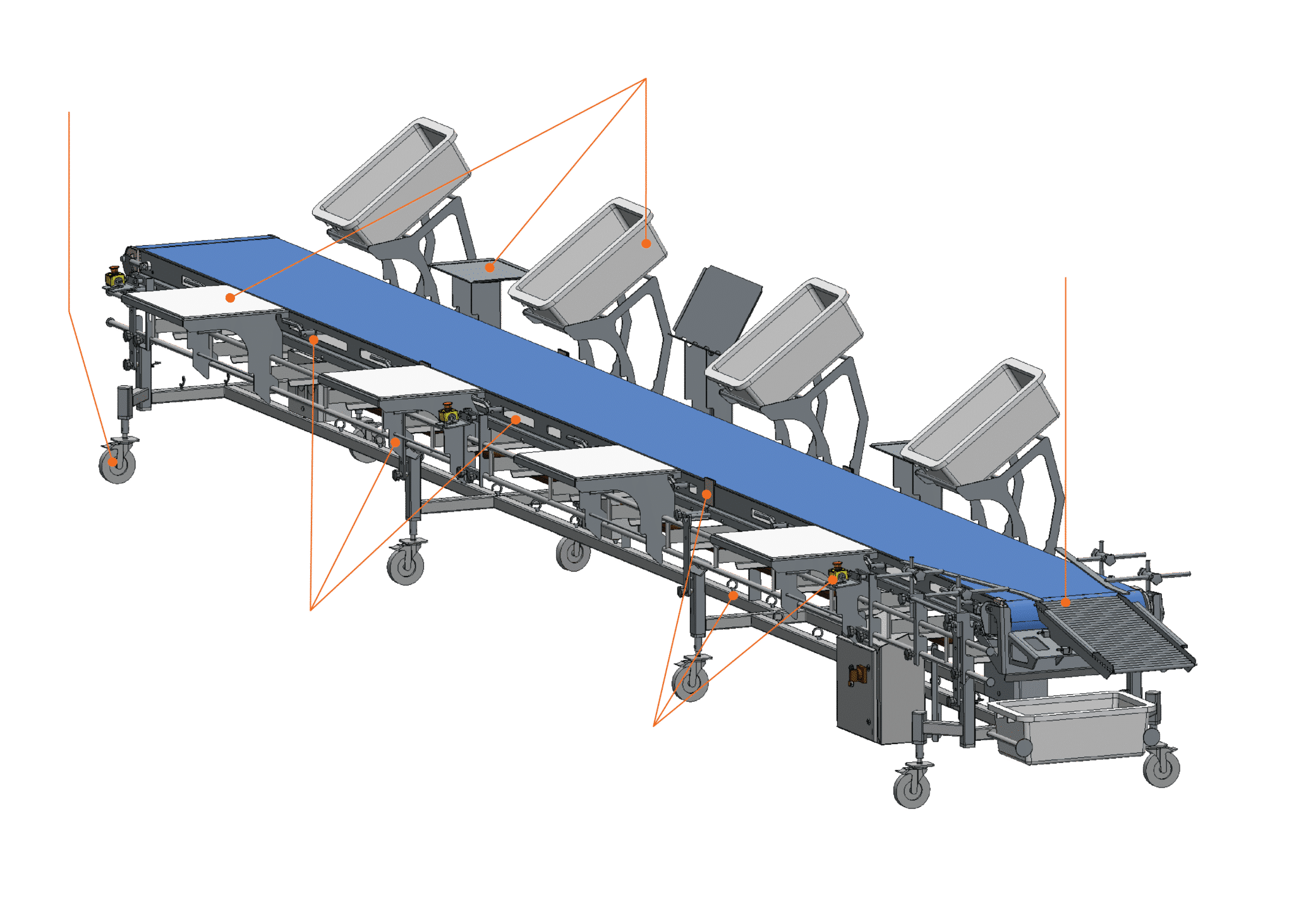

Click the icons below to explore the key features of this conveyor system:

MOVABLE ACCESSORIES & WORKSTATIONS

With an adjustable guide rail, workers can easily interchange and move accessories such as stainless-steel tables, cutting boards, and tote bins, which allows the sandwich-making process to be altered depending on the recipe being produced.

EASY MOBILITY

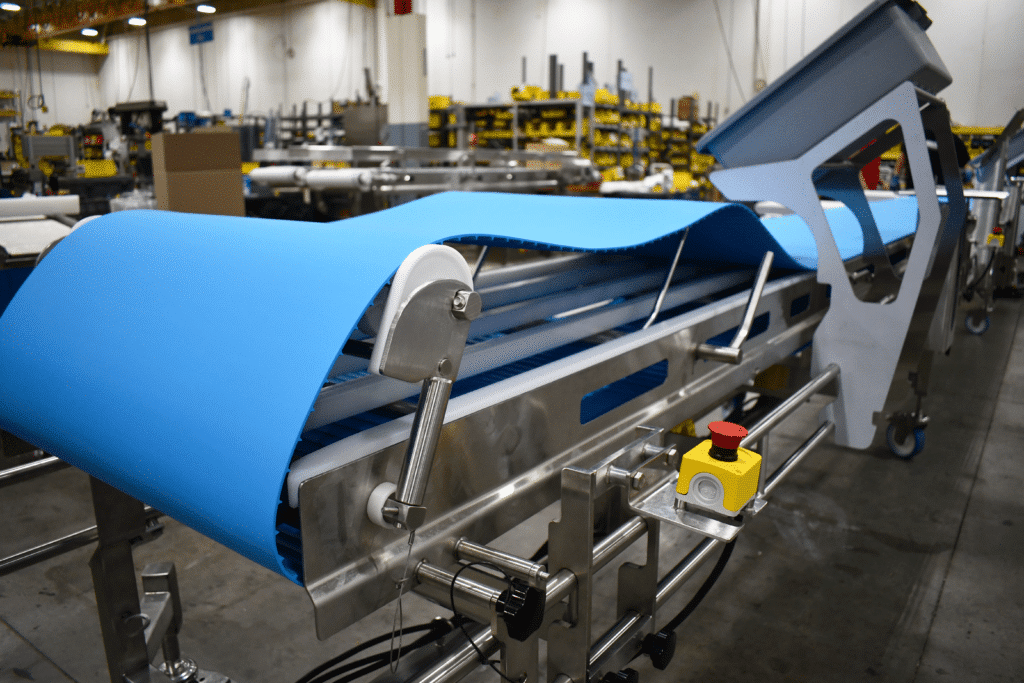

The client needed this conveyor system to be mobile so it could be moved into position for cleaning or to adjust its position in the production line configuration. The conveyor was designed with sanitary-grade locking casters, which allow for quick and easy adjustments while locking the conveyor in place when it is in use.

QUICK CLEAN FEATURES

Dorner’s AquaPruf Ultimate is designed to meet the most stringent 3-A sanitary requirements for handling raw food and dairy products. This ready-to-eat system also features a quick-clean design with belt lifters, frame cutouts, and tool-less disassembly of workstations. These features help to cut down cleaning and line change over time, maximizing efficiency for this client’s operation.

SAFETY FEATURES

Safety is always a top priority. This conveyor system includes movable emergency stops that can be placed anywhere along the full length of the conveyor. Sanitary cable management loops are built into the base of the frame, keeping electrical components and wires aligned and out of the way. Additionally, hygienic guards are in place to eliminate potential pinch points, keeping staff safe while they work around the conveyor.

OUT-FEED

The conveyor system out-feed features a declining roller transfer, with adjustable guide rails to direct finished product into a bin or to the next step in production.

With this entire system, the grocery store supplier has the ability to run multiple product lines efficiently with little downtime because of the easy changeover features designed by Dorner. This solution was further customized to the exact needs of the customer by including a versatile guide rail solution that allows for easily movable accessories along the entire length of the conveyor.

Safety & Ergonomics

All of Dorner’s conveyors are meticulously created to improve workers’ safety while in operation. This conveyor is built with casters for easy movement around the facility depending on the facility’s desired layout, as well as for effortless maneuvering for cleaning. Even the height of the system was carefully considered for desirable ergonomic height for staff to construct the ready-to-eat meals without straining to reach materials.

Safety is also of utmost importance for any Dorner conveyor solution. This conveyor features multiple emergency stops that can be moved with each workstation to ensure they are always within reach. Electrical outlets built into the underside of the conveyor are also designed with water-safe covers to eliminate potential hazards when cleaning.

Looking to Optimize Your Ready-to-Eat Production Line?

Contact us to learn more!

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy