By AJ Naber

Senior Design Engineer – Dorner Manufacturing

An essential part of any food inspection process is the ability to quickly and effectively remove questionable product from the process flow. And a key component of that inspection process is metal detection. Once contaminated product has been detected there are many methods of product removal – from a simple stop-on-detect mechanism to a more complex system such as a retractable tail. The application, and often the space available to design the supporting conveyor system, will dictate which option to use.

Recently, I designed a retractable tail metal detection conveyor for a customer that produced frozen French fries. Based on the configuration of the existing processing line, a retractable conveyor was the best fit for their application. The conveyor primarily runs in the extended position and as French fries successfully pass through the metal detector they continue on the extended conveyor to a take-away conveyor. When the metal detection system detects metal within the flow of French fries, the retractable tail conveyor pulls back and creates a gap to allow the product to fall onto a second conveyor for disposal.

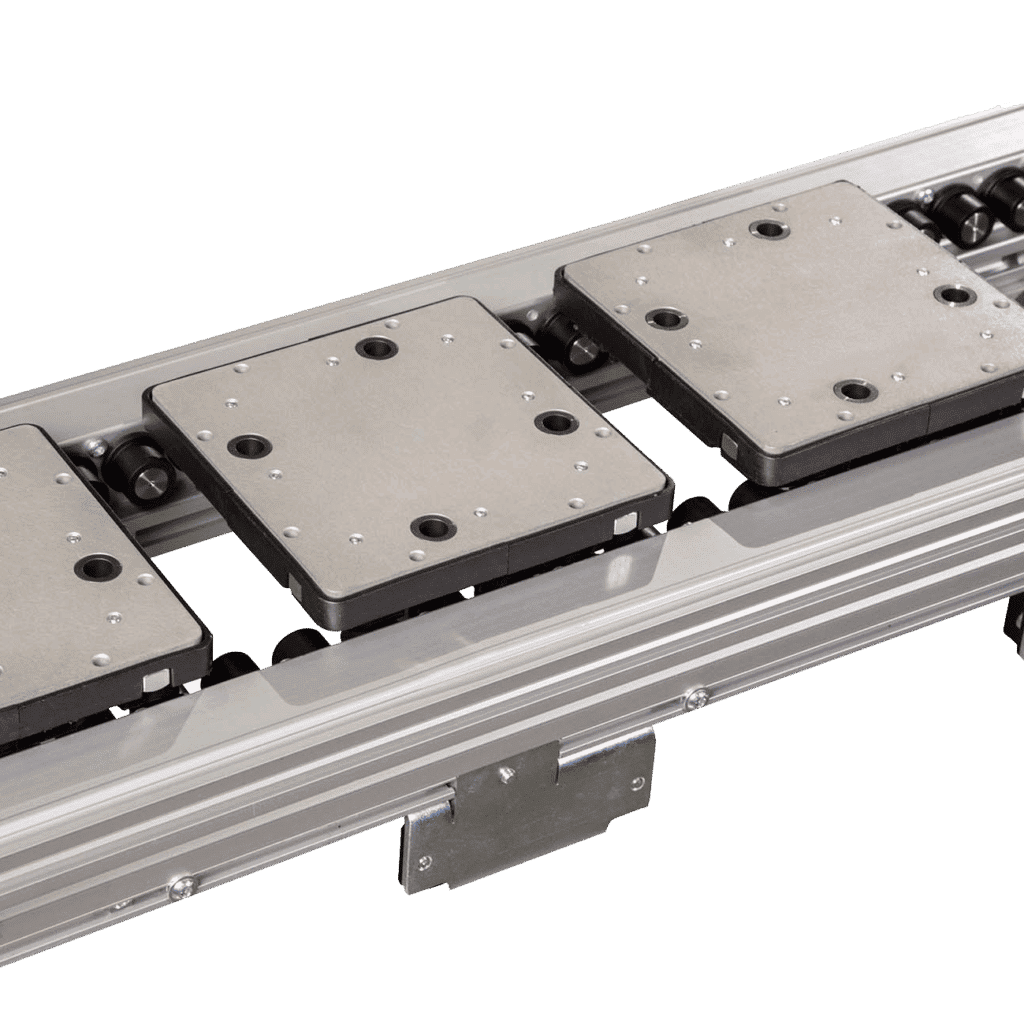

The retractable tail assembly utilizes a drawer style design. The framework of the retractable tail is housed within the conveyor frame and is mounted to stainless steel guide rails. During the normal operation when French fries successfully pass through the metal detection system, the retractable tail is fully extended. To retract the tail, a pneumatic stainless steel cylinder is actuated, pulling the tail 14 inches inside the conveyor, which then allows the rejected product to fall.

Based on the parameters of the application, a retractable tail was the most efficient and effective option for that customer. While that was certainly one of the more complex metal detection conveyors I’ve ever designed, most are fairly straightforward and simple.

Again, the goal of a metal detection conveyor system is to efficiently remove the contaminated product. The most basic design is stop-on-detect. When the metal detector flags a questionable product, the conveyor line will stop, allowing an operator to manually remove the product. The operator then activates the line and production resumes. This design is the simplest and generally least expensive option available.

Nevertheless, many processing lines utilize more automation, which requires some type of reject mechanism beyond human intervention. Push-on-detect, air blast and diverter arms are some of the common reject mechanisms on metal detection conveyor systems.

Just as it sounds, push-on-detect involves a pusher mechanism mounted to the side of the conveyor. The pusher face is actuated (generally pneumatically) when the metal detector flags a product for rejection. The “push” is timed with the product flow so that when the flagged product arrives at the pusher, it activates to remove the flagged product to a reject bin or a separate reject conveyor for disposal.

Air blast operates similarly to that of push-on-detect. Rather than a pusher, a flagged product is removed from the conveyor by a blast of air. This type of reject mechanism is ideal for light-weight products requiring a more finite reject.

A diverter arm swings out across the width of the conveyor belt to guide flagged product to a reject lane or bin for disposal. Bulk materials are best suited to divert-rejects as a section of product is removed every time the arm is actuated.

All three reject mechanisms work well to remove questionable product from a processing line. The nature of the application and the product being scanned will help determine which type of reject mechanism is best.

The area within the metal detector through which product travels is known as the aperture. Within the aperture there needs to be room to accommodate both the conveyor and the product. Most metal detectors require a metal-free zone of approximately 1.5 times the aperture height. This constraint presents a challenge because everything on the conveyor system within this metal-free zone needs to be made from plastic.

The stainless steel conveyor frame also needs to be split to run plastic through the aperture and within the metal-free zone. That’s why it’s important to properly size a metal detection system to the application. Customers will often come to us saying they need to retrofit an existing or pre-purchased metal detector with new conveyor equipment, but the aperture is considerably larger than the application requires. It will still do the job, but now the required metal-free zone is larger, which can limit some of the options available for the conveyor and reject system. I recommend considering all supporting equipment including the conveyors and reject method when selecting a metal detector for a processing line. Think of the metal detector and supporting conveyor line as one integrated component.

Selecting a metal detector with an aperture that may be too big for the product may also limit space where accessories can be mounted to the conveyor frame. Remember, a larger aperture casts a larger metal-free zone around the entire system. And if the metal detection system is located in a fairly confined space, available space on the frame to mount the reject mechanisms may be limited. From an engineering standpoint it’s always a challenge to make the system as sanitary and compact as possible while still achieving what the customer needs.

Ultimately any design we make needs to be safe, and often, safety and sanitation don’t go hand in hand. Ideally we want as little human intervention in the reject mechanisms as possible, so we’ll add various guards to eliminate access to dangerous areas. However, with every component that is added to the conveyor you can decrease its overall level of sanitation. It’s a balancing act. Our job is to design a metal detection conveyor system that’s very sleek, smooth and uninterrupted, but at the same time provides the highest level of safety.

No two metal detection conveyor systems are identical. However, when specified properly, they can serve an integral role toward adding value and efficiency to any production line.