- What environment does it need?

- Will it need an incline or decline?

- Does it need to rotate or turn corners while it’s being conveyed?

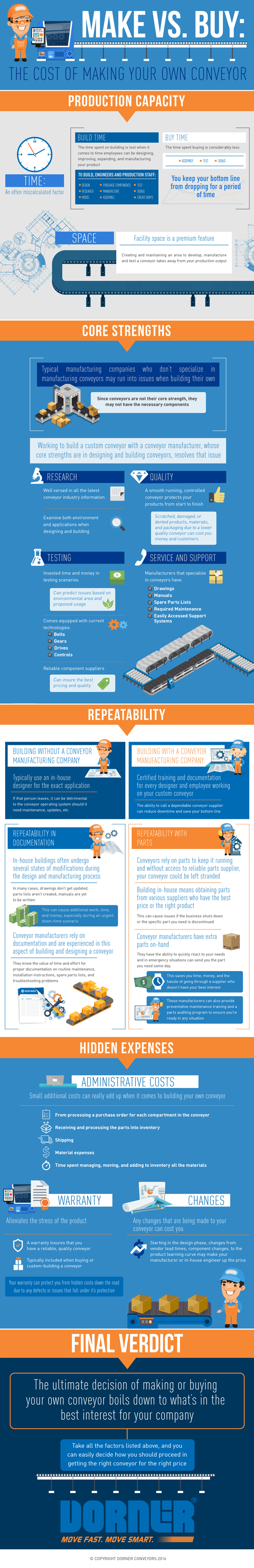

Adding to this decision-making process is the option of having to determine whether you make or buy your new conveyor system. As with most decisions, there are pros and cons to each side.

Things to Consider When Calculating Conveyor Costs

If you do choose to build your own conveyor, one of the pros is that you’re guaranteed to optimize the space available in your warehouse. You understand the best dimensions and configuration and can customize your conveyor system to meet these needs. Additionally, building a conveyor belt in-house may have cheaper up-front costs, as you can handpick parts from a variety of suppliers who offer the best price.

You also aren’t required to purchase a warranty on your own product, reducing costs even further. Without a warranty there’s no guarantee in the protection against future defects or mechanical issues, which is why many conveyor manufacturers, like Dorner, provide warranties when you build or purchase any conveyor system from them.

There are potentially small hidden costs that will add up over time with any conveyor, such as the administrative costs of processing a purchase order, the warranty, any changes made in the design process, customization, etc. These costs don’t have to be a surprise. It’s these added expenses that add to the pros of choosing the right conveyor manufacturing company.

Get the conveyor you need

While your company may specialize in a product that utilizes a conveyor belt, building the conveyor belt system may not be your specialty. Outsourcing to a conveyor manufacturing company provides a guaranteed quality solution, with your conveyor belt built with the most current technologies, reliable component suppliers, and consistent service and support.

In the end, deciding between making your own conveyor or buying one from another company comes down to weighing the pros and cons and analyzing what will be in the best interest for your company, your budget, and your product. For a comprehensive look at the process of making versus buying a conveyor system, check out our latest infographic above or call a Dorner expert to talk about how we can get you started on finding your next conveyor today.

[sc name=”Social Icons”]