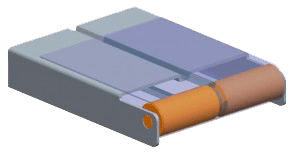

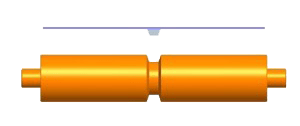

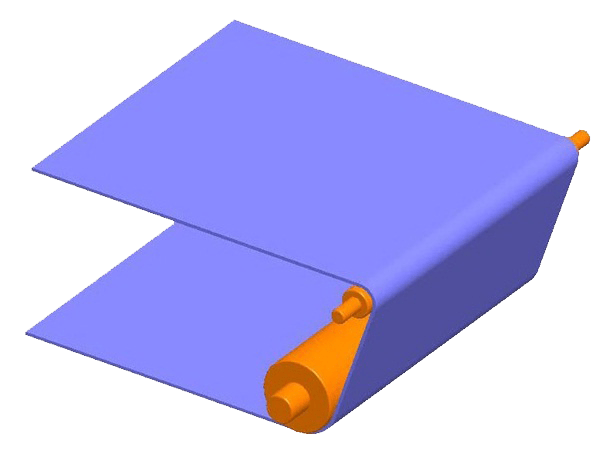

V-Guiding

V-guided belts have a “v” shaped plastic adhered to the back of the conveyor belt. This “v” then fits in a groove that runs the length of the conveyor and pulleys. V-guide continuously tracks the belt and keeps it running straight. For best bonding results the V-guide material, which is generally PVC or urethane, should be the same was the belt being used. However, there are belts that cannot be used with V-Guiding such as, Teflon, polypropylene, and silicon-based belts. These belts are usually used in very specific applications like high heat or some food applications. For most, V-guiding will work for their applications.