- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

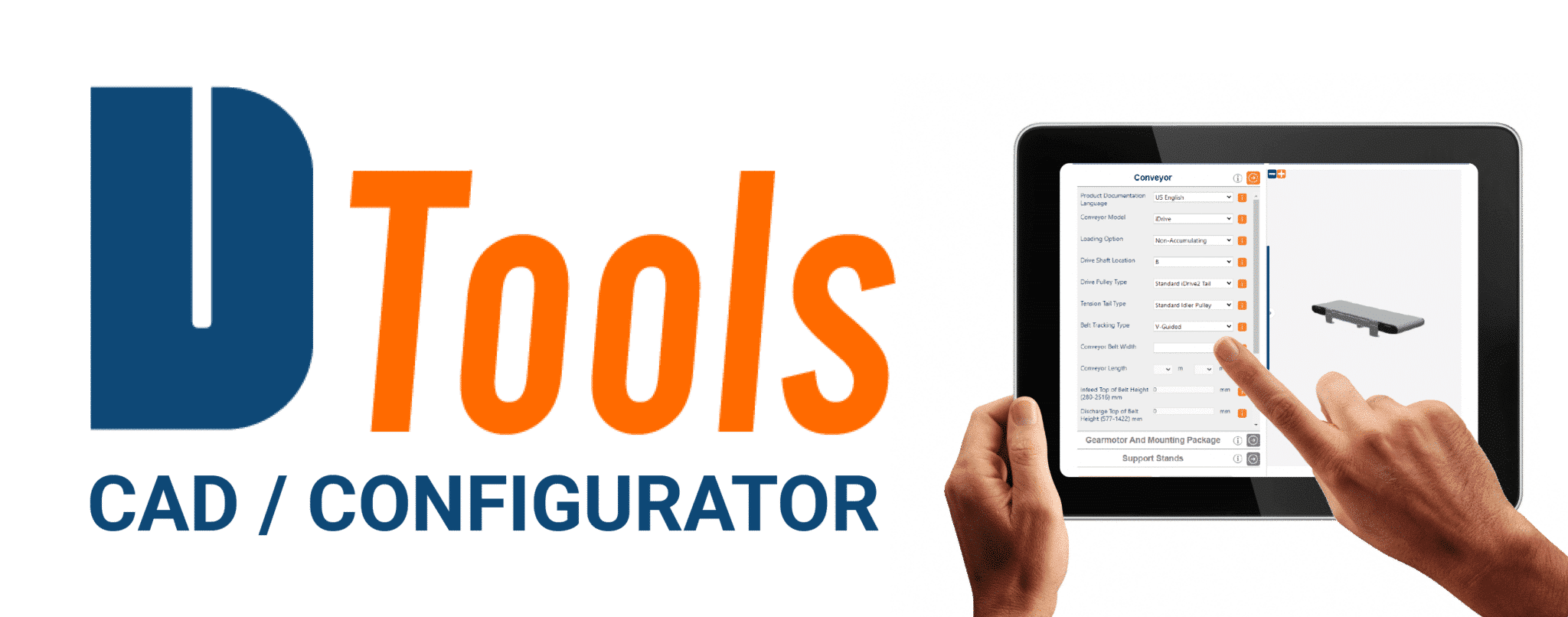

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

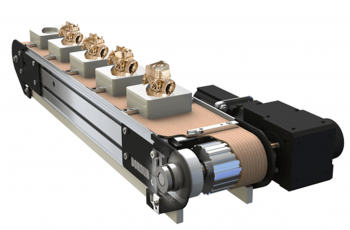

Industrial Conveyors

Features & Benefits

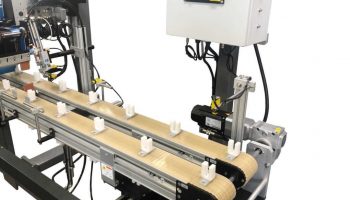

Industrial automation conveyors are a crucial part of any production facility to move parts and products from one place to another during specific steps in the production process. Precision industrial conveyors in particular are designed for automation and offer highly accurate product control. These conveyor systems transport products at a precise time to an exact location, ensuring that everything is always in the correct phase of the production line.

Industrial conveyors are ideal for a wide range of industries including consumer goods, metalwork, product assembly, warehousing, and e-commerce.

Features

- Precise product positioning conveyor

- Variety of belts, rollers, and other options for easy line transportation

- Flexibility to grow according to your needs

- Solutions for both small and large products

- Unique indexing and positioning abilities

- Vacuum and backlit conveyors

- Lift gates options

- Leading sorting technologies

Benefits

- Versatile layout flexibility

- Easy to reconfigure and add on to

- Highly accurate positioning and routing

- Improved production line efficiency

- Easy customization and integration

Industrial Product Lines

Small, lightweight conveyors designed for tight spaces and small parts handling.

Conveyors ideal for medium-weight products, consumer goods, and e-commerce.

Durable, heavy-duty conveyors designed to handle weights up to 1000 lbs.

Industries & Applications

Industrial conveyor belts are utilized in a range of industries, including the automotive, food processing, packaging, metalworking, and pharmaceutical industries. These industrial conveyor belt systems excel in a number of applications such as accumulation, assembly automation, part handling, and packaging. These conveyors transport items from boxes, packages, and totes to edible products such as fruits and meats.

Automation conveyor belts are also used in many industries, especially those that require flexibility while maintaining precision when moving pallets. Automated systems reduce costs and downtime, all while saving time and resources. Industries that will benefit from automation conveyor belt systems include medical product and device packaging, automotive assembly, and appliance manufacturing.

Automation

Integrators

Material Handling

Metal Working

E-Commerce

Packaging

Medical

Pharmaceutical

Conveyor Insights

Picking a Winner - Robotics Integration Conveyors

Farason Corporation chooses Dorner’s 2200 Series conveyors to integrate with its robotic machine assembling coin proof sets.

Understanding Precision Conveyance

Precision conveyors offer the highest degree of accuracy and repeatability, ensuring product quality and easy robotics integration.

Tervis Chooses Dorner's Precision Belt Technology

Dorner’s Engineered Solutions team helped this custom tumbler manufacturer automate their production line with precision move conveyors.

Contact the Conveyor Experts!

Our team is standing by to answer any questions you may have and help you improve your production line with an industrial automation conveyor system.

Medium Duty Conveyors

Conveyors ideal for medium-weight products, consumer goods, and e-commerce.

Heavy Duty Conveyors

Durable, heavy-duty conveyors designed to handle weights up to 1000 lbs.

Ready for a New Industrial Conveyor System?

Sign up for DTools to start configuring your custom conveyor.

OR

Contact us for a no-obligations quote!

Create your own custom conveyor with Dorner s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy