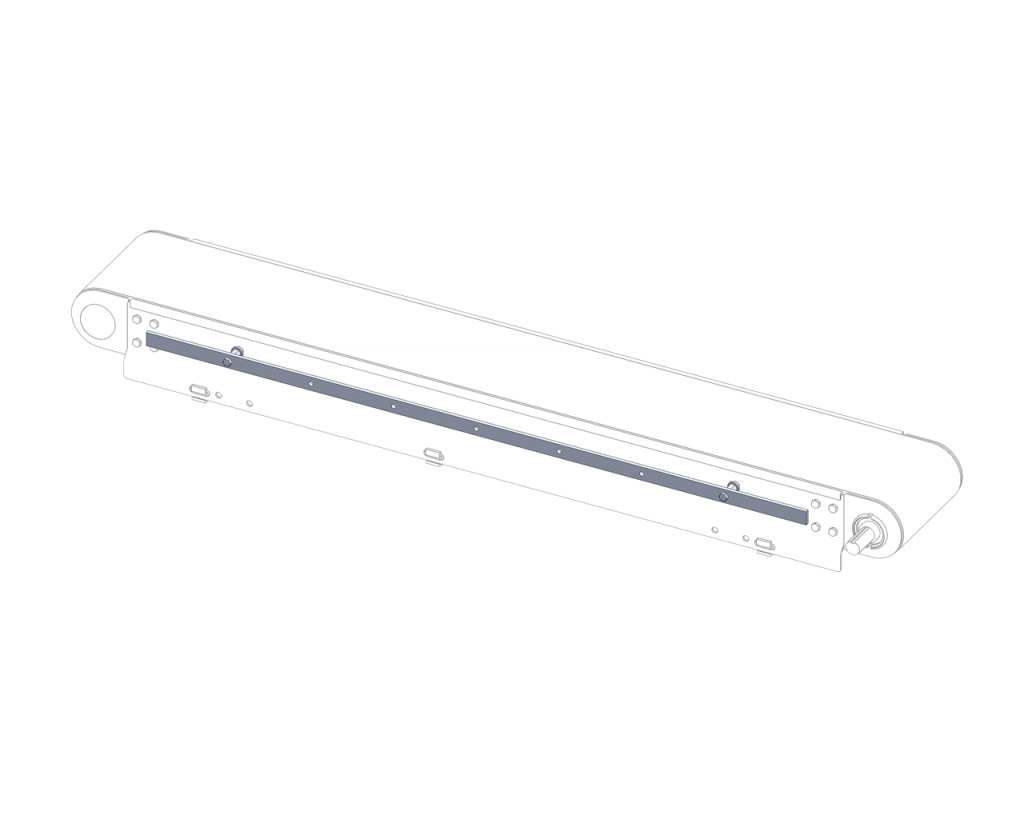

AquaGard 7350 Conveyors

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of AquaGard 7350 Conveyor:

- Rugged and Durable Design

- 304 Stainless Steel frame features open design with minimal horizontal surfaces

- Designed for wipe down and low pressure wash-down with non-caustic chemicals

- V-guided belt tracking on belted models

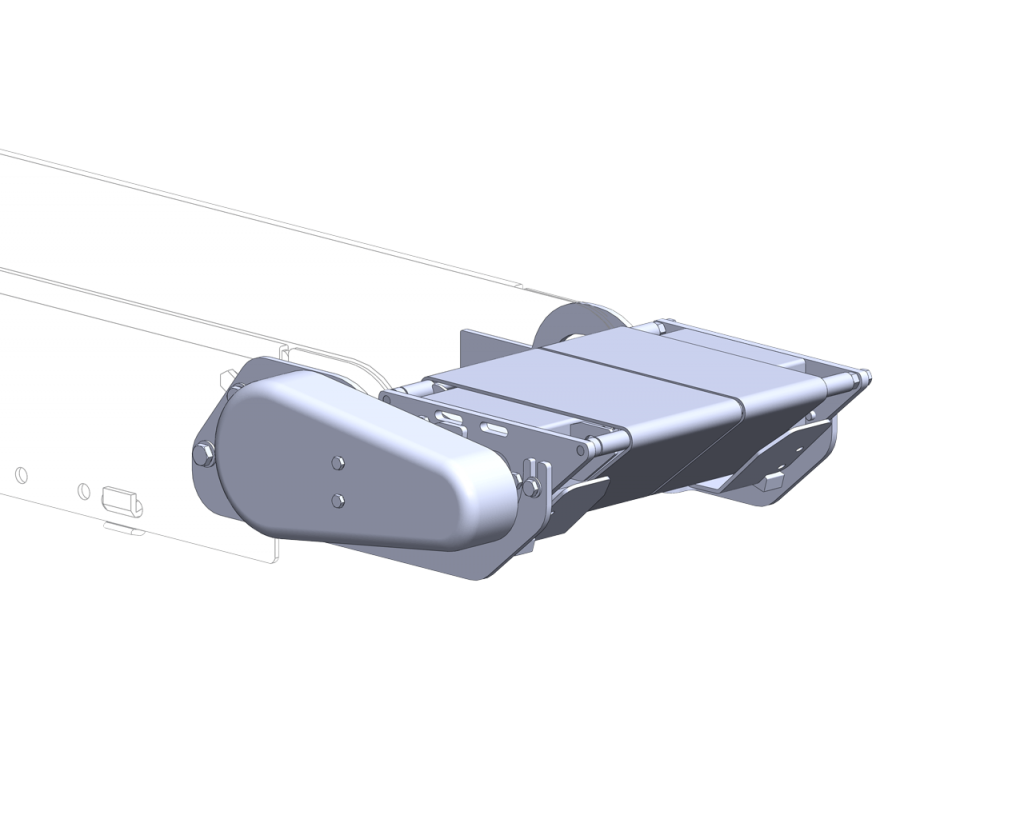

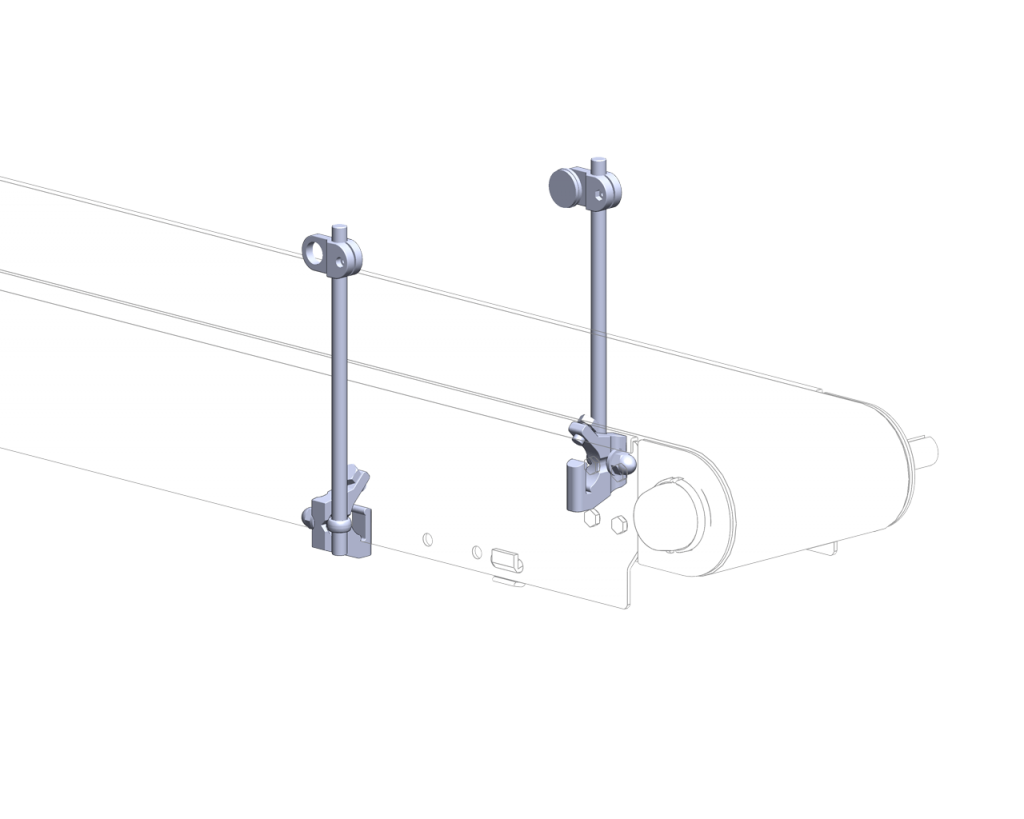

- Tip-up tails for access inside the conveyor for cleaning and maintenance

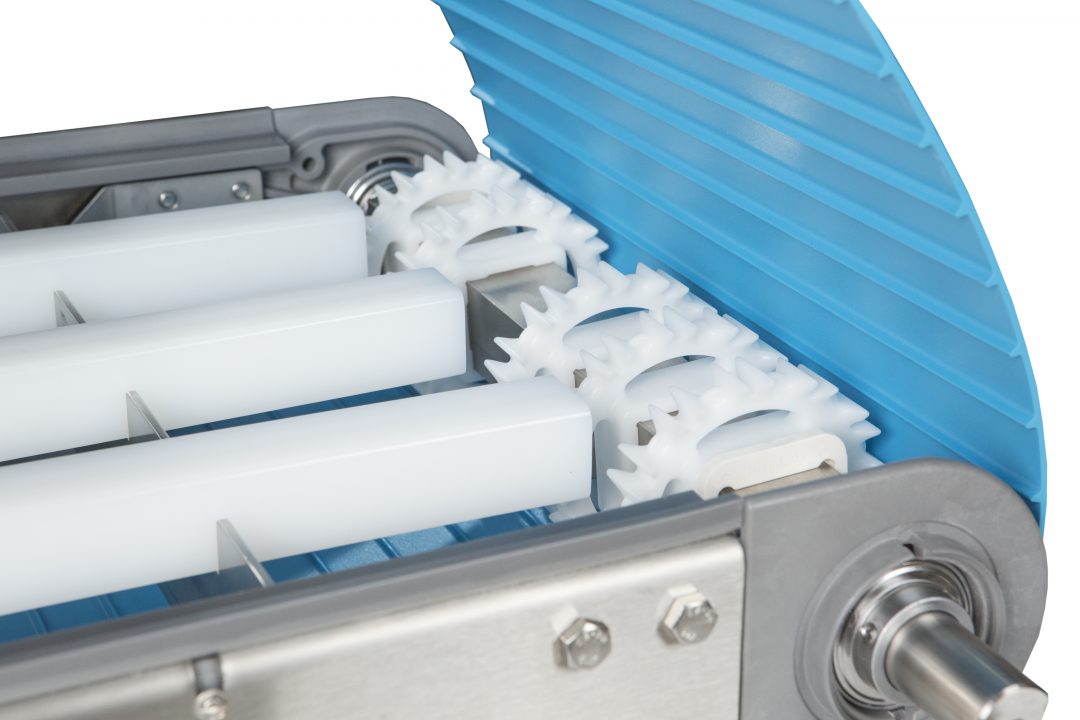

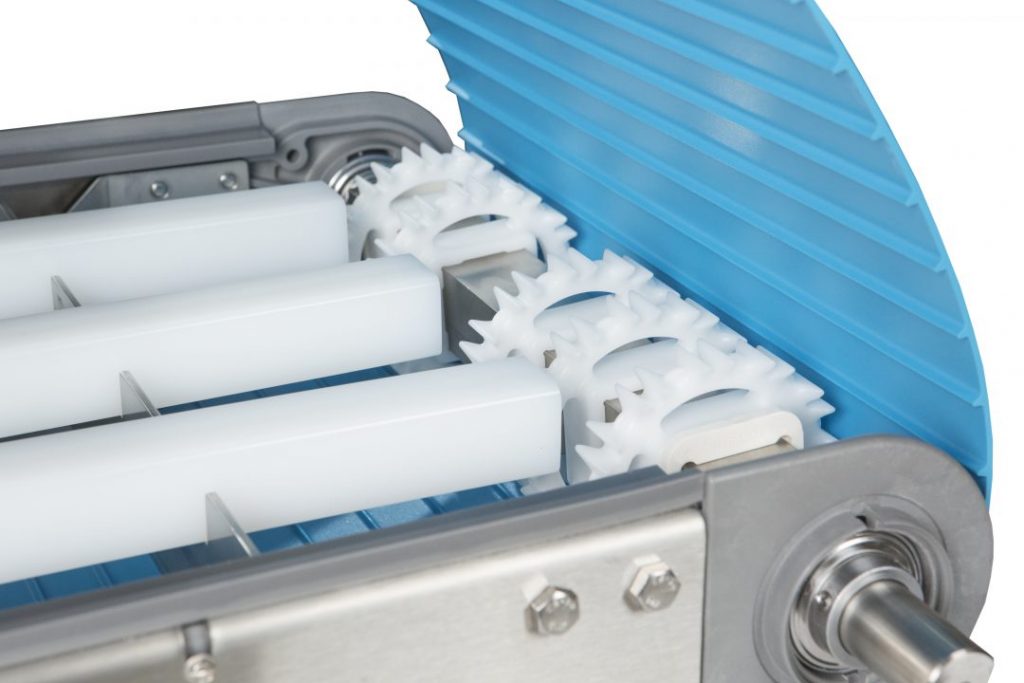

- Safest chain in the industry with chain openings less than 4 mm even on curves

- Unique chain design virtually eliminates friction providing capacity for up to 4 curves on a single conveyor

Specifications

- Belted, Cleated Belt, Modular Belt, Modular Cleated Belt Models and Positive Drive Options

- Loads up to 341 kg (750 lbs)

- Widths: 152 mm (6 in) to 914 mm (36 in)

- Lengths: 914 mm (3 ft) to 25000 mm (82 ft)

- FDA approved belting and plastic components

- 304 Stainless Steel frame

- Available in straights, curves or Z-Frame configurations

- Options include:

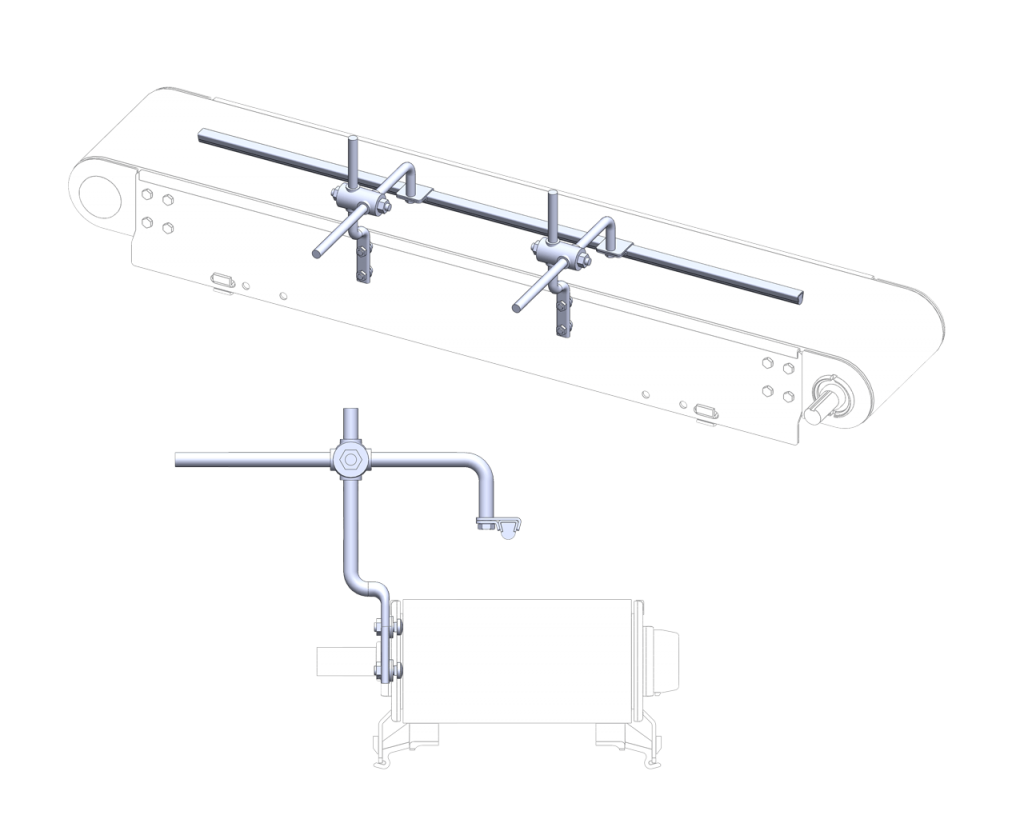

- Nose bar transfers

- Powered and roller transfers

- Variety of guiding

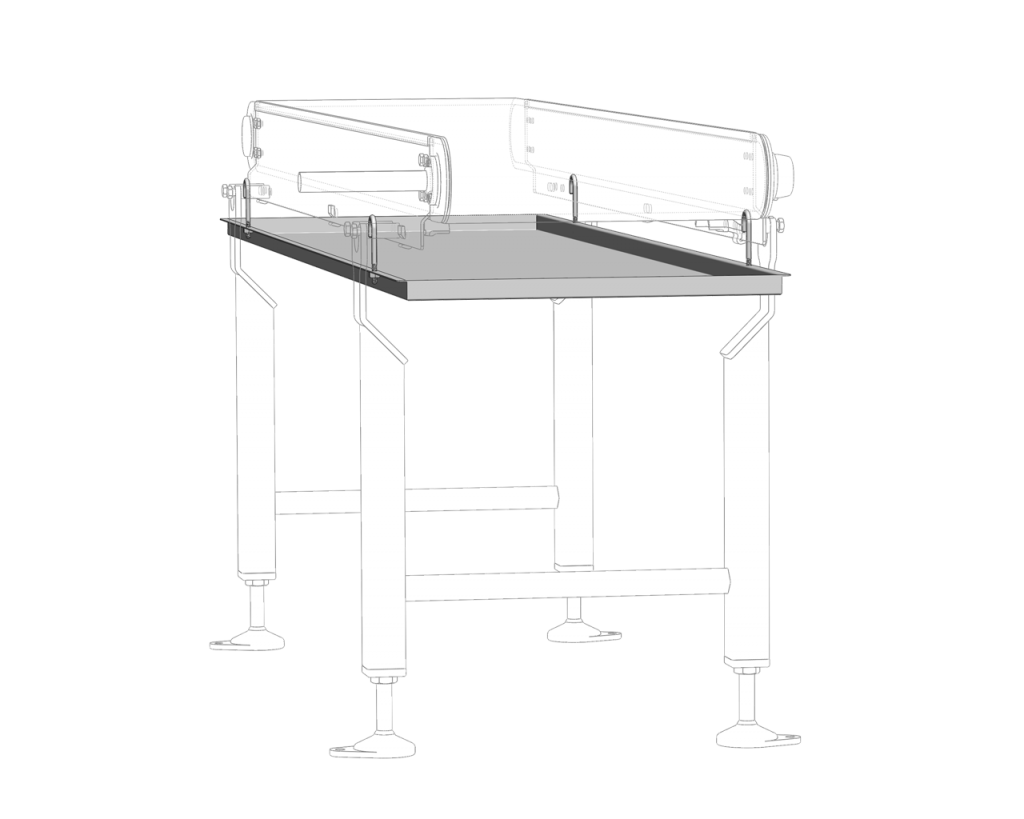

- Chutes, drip pans, hoppers and more

Industry Ready

- Designed and manufactured to food equipment standards

- BISSC certified conveyors

- FDA approved materials and components

- Washdown rated gearmotors and controls

A Focus on Speed

- Dorner sets the industry standard for rapid delivery

- Sanitary conveyors ship in as little as 10 business days

- Fast and effective design reduces cleaning preparation time

- Accessories

- Profiles

- Fabric Belting

- Modular Belting

- Support Stands

- Gearmotors

- Drive Mount Packages

- Manuals & Literature

Accessories

Profiles

Fabric Belting

Modular Belting

Support Stands

Gearmotors

Drive Mount Packages

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| AquaGard 7350 Series Manual | 76 | 12.73 MB |

| Literature | Pages | File Size |

| Sanitary Conveyor Brochure | 4 | 3.2 MB |