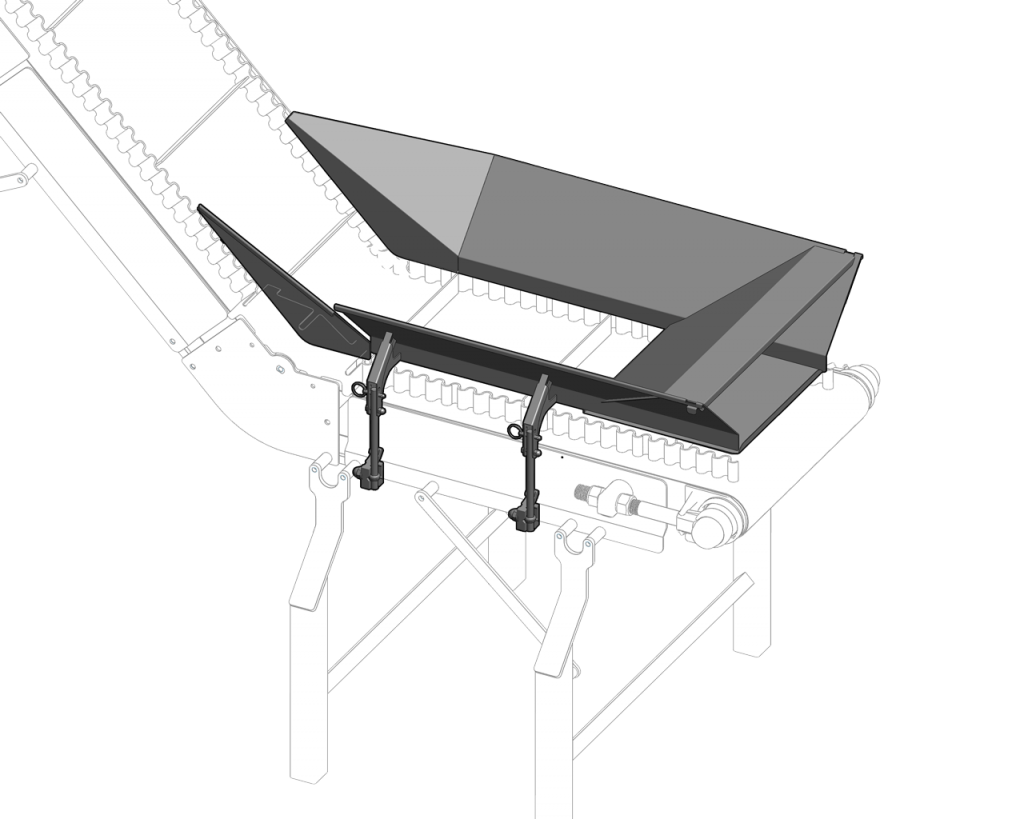

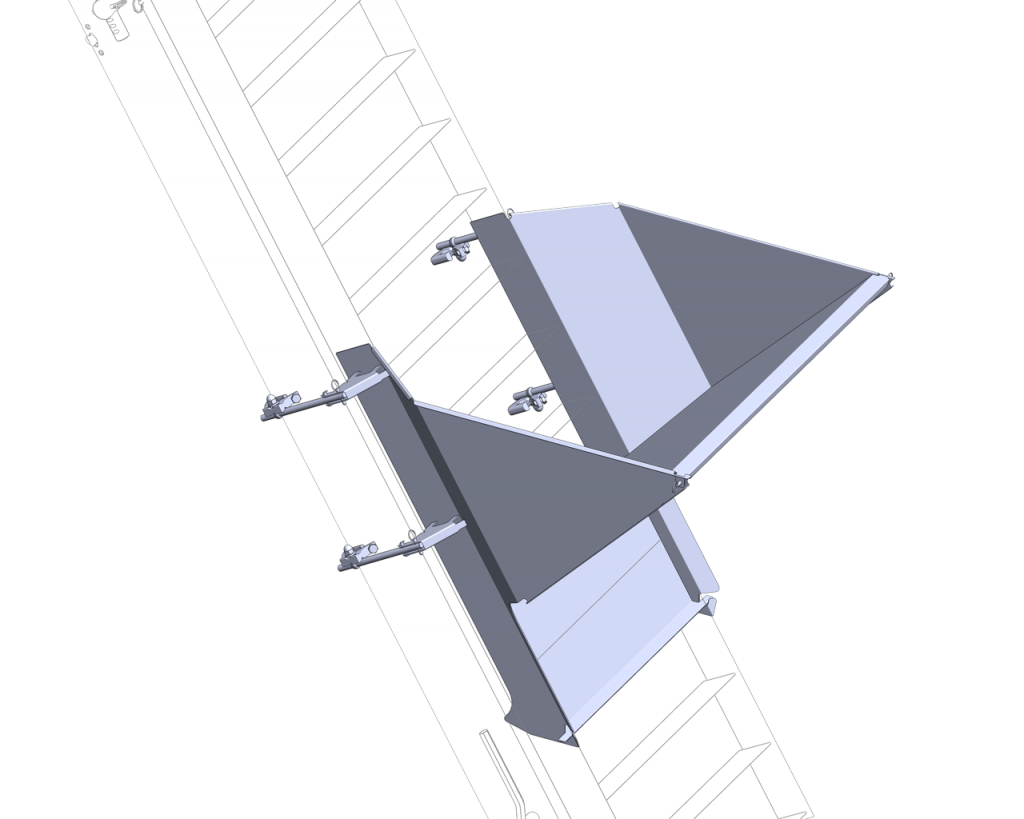

End Drive

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of 7360 AquaGard Flat Belt End Drive Conveyor:

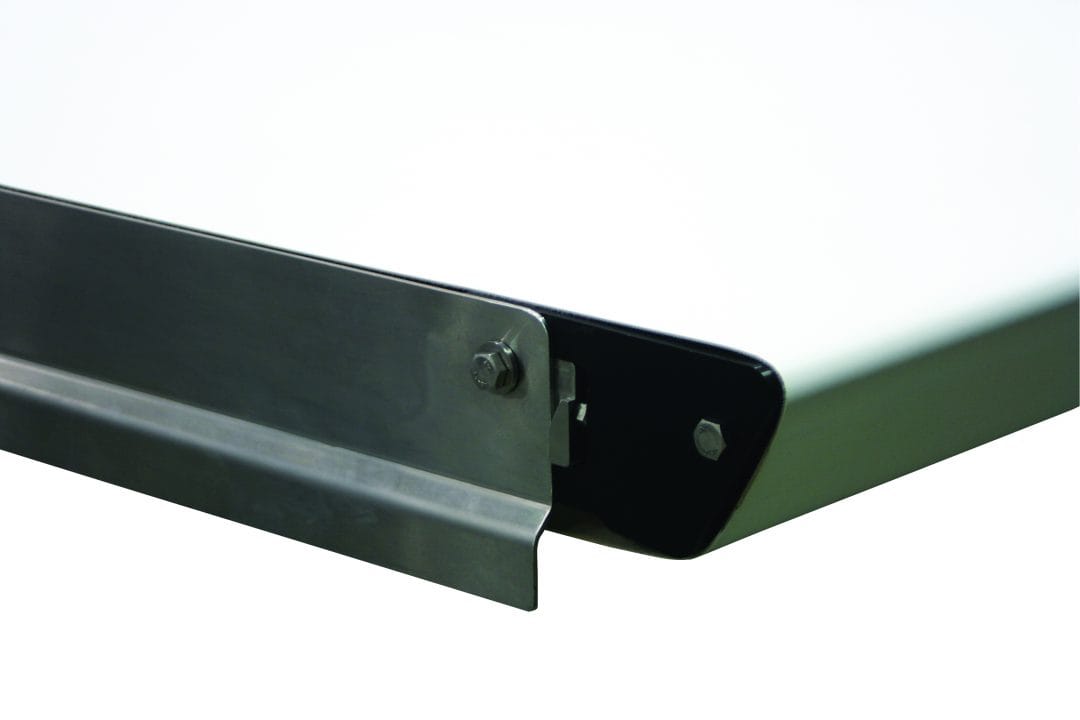

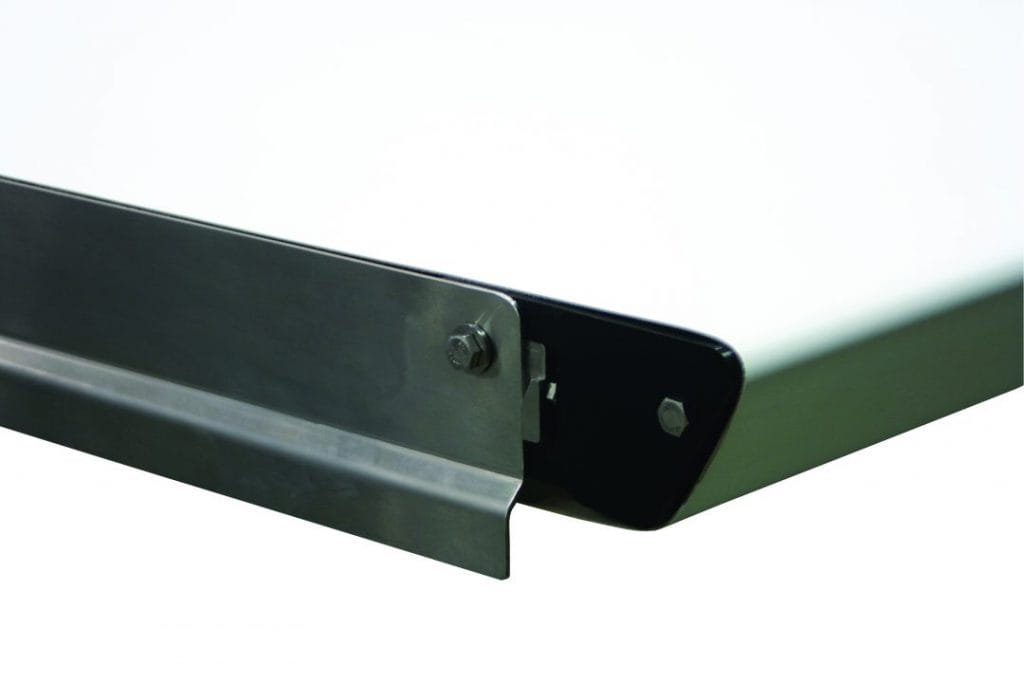

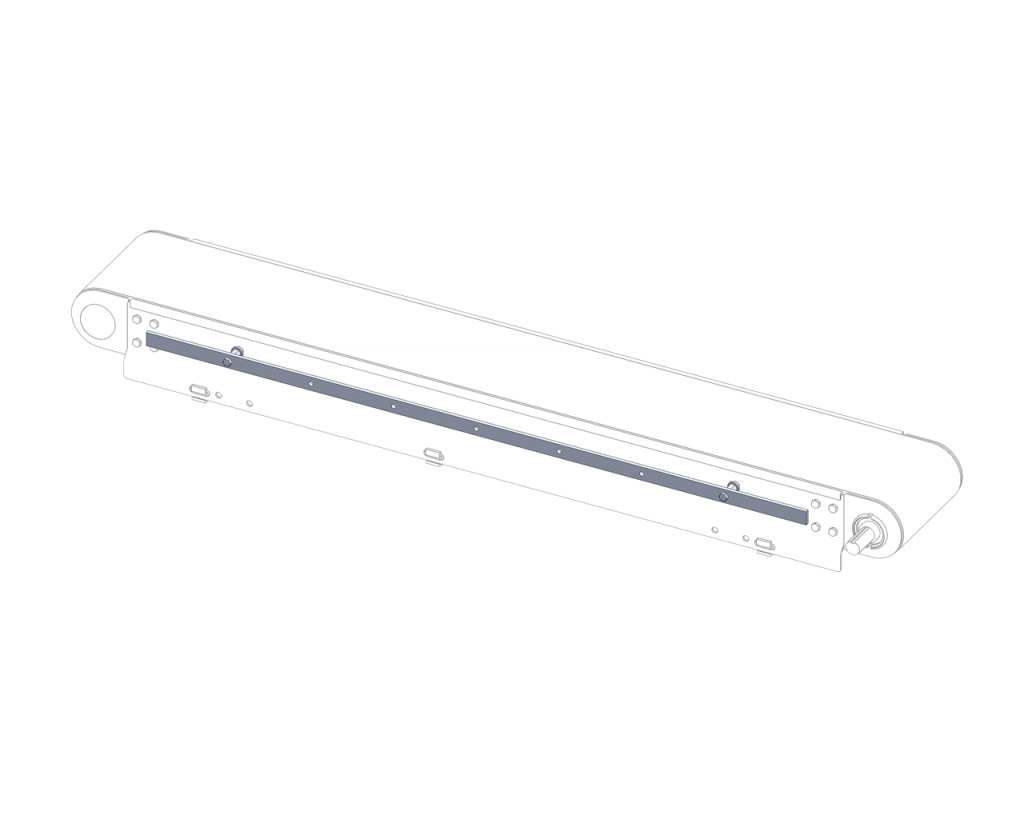

- Frame is constructed of TIG welded 304 stainless steel and features open design with minimal horizontal surfaces

- Hard coat anodized aluminum wear strips located in welded cross members for durable belt support

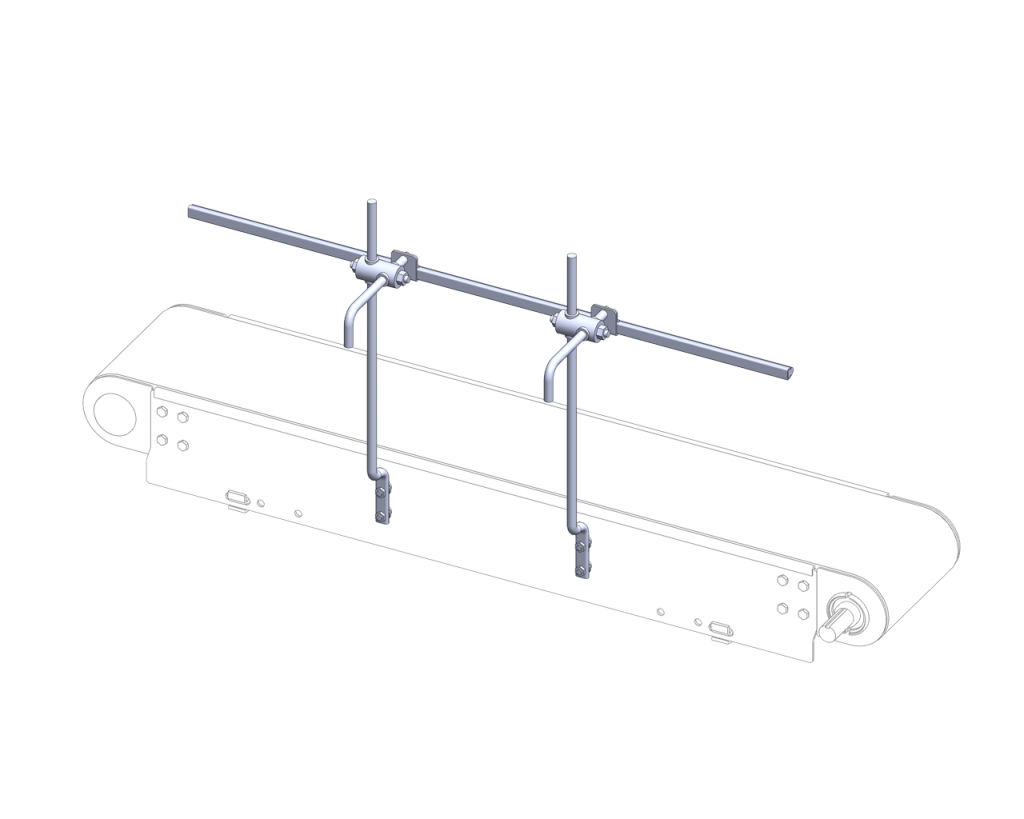

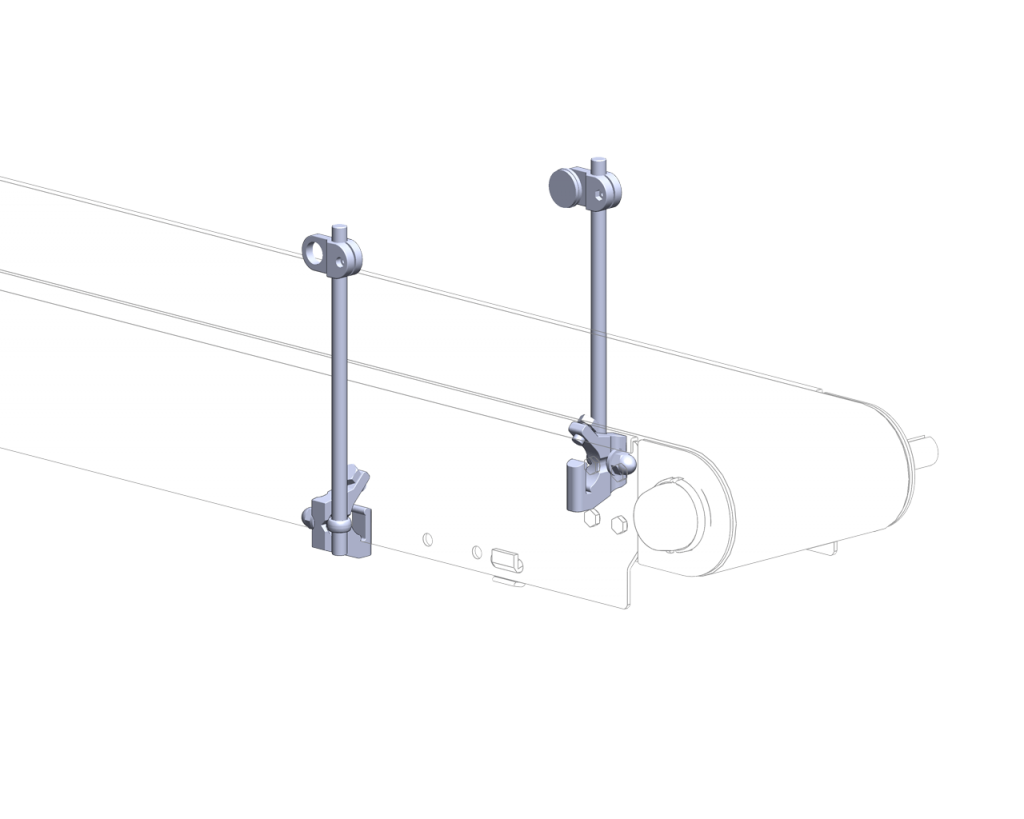

- Mount controls and accessories fast with no drilling required includes adjustable guiding, photo eyes, low voltage wires, controls, and air tubing

- Flexible guiding packages for a variety of applications including fully adjustable single and twin rail, and high side

- Spindle has groove for V-guided belt and optimum performance

- Integrate jack-screw system in tails for belt take up and easy tracking adjustments

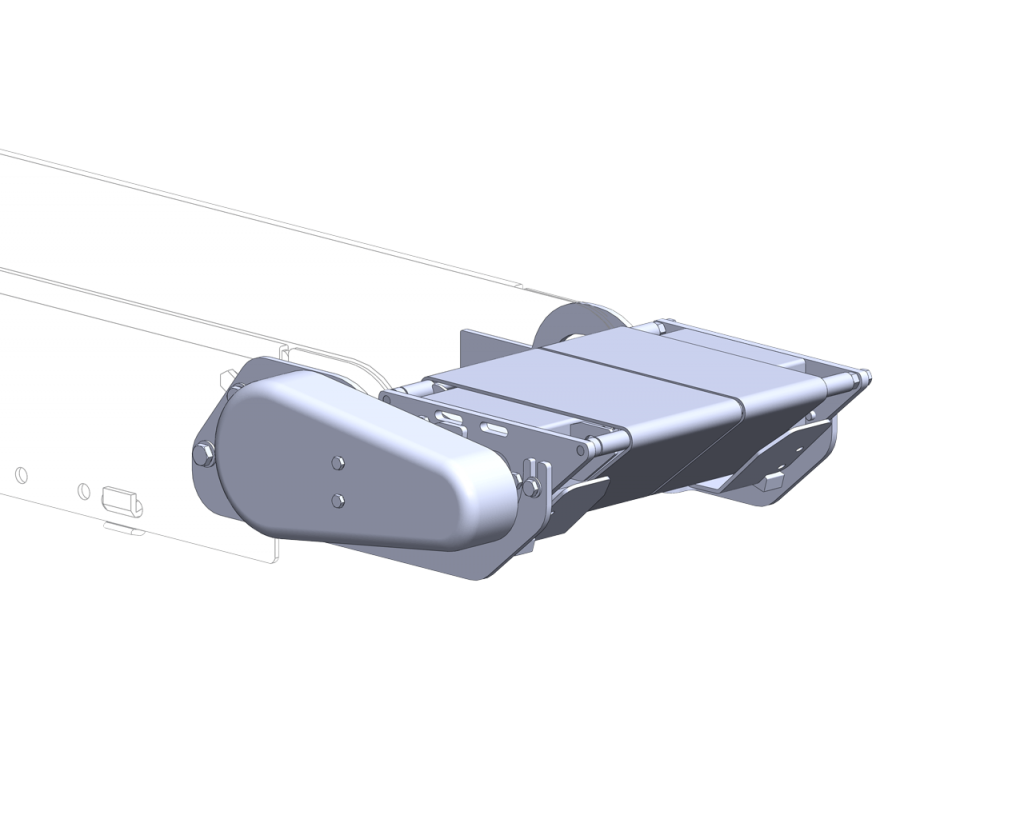

- Nose bar idler tail (optional) has 1” diameter pulley for small product transfers

- The Powered Transfer (optional) has 1/2” diameter pulleys for maintaining speed through transfer

- Roller Transfer Plate (optional) for smooth product transfer in minimal added length

- Conveyor is suitable for wipe-down and occasional pressurized liquid spray cleaning up to 100 psi max

Specifications

- Loads up to 750 lbs (453 kg)

- Belt speeds up to 300 ft/min maximum (91 m/min)

- Belt widths: 3.75” (95 mm) to 52” (1,321 mm)

- Total lengths: 3’ (914 mm) up to 83’ (25,298 mm)

- Wearstrip material is hard coat anodized aluminum

- BISSC Certified

- One revolution of the drive pulley moves the belt approximately 11”

- TIG welded 304 Stainless Steel Frame

- Hard Chrome Coated Bearing with FDA H1 Food Grade Grease

- FDA approved belting and plastic components

Accessories

Profiles

Belting

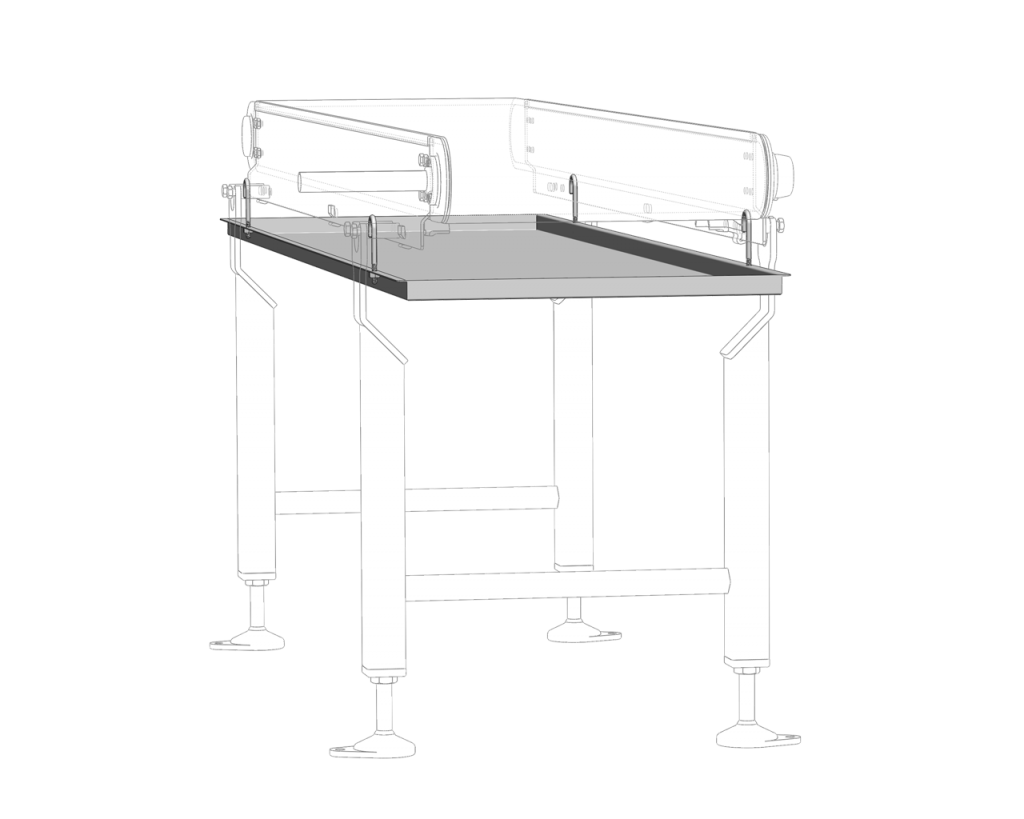

Support Stands

Gearmotors

Drive Mount Packages

Manuals & Literature

| Engineering Manuals | Pages | File Size |

| Sanitary Overview | 52 | 8.34 MB |

| Literature | Pages | File Size |

| Sanitary Conveyors Line Card | 6 | 5.97 MB |