- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Sanitary Conveyors for Ready-to-Eat Meals & Food Delivery

In ready-to-eat foods and prepared meal production facilities, efficiency, flexibility, and hygiene are essential to keep up with consumer demands and industry regulations. Dorner’s RTE Conveyors meet the unique needs of the ready-made food product industry with easy-clean features, ergonomic design, and seamless automation integration capabilities.

What makes Sanitary Stainless Steel Conveyors Ideal for Fresh Meal Processing

- Easy-to-Clean Materials

- Dorner’s sanitary conveyors are designed with the highest level of hygiene in mind and offer the industry’s quickest line changeover.

- Modular Workstations

- Hardware-free mounting for totes stands, cutting boards, and packing stations are easy to move as production needs change.

- Ergonomic Design

- Our read-to-eat food production conveyors come standard with enhanced safety features and adjustable workstations to reduce strain and eliminate potential hazards.

Benefits of Dorner's

Sanitary Conveyors

- Custom Conveyor Solutions

- With the widest range of customizable sanitary conveyor options, Dorner stands out as the premier choice for fresh food and meal kit producers.

- Production Improvement

- Dorner’s simple sanitation solutions and easy integration with automation technology help ready-to-eat food producers improve product quality and throughput.

- Maximize Uptime & Throughput

- Dorner helps prepared meal producers maximize uptime with hygienic conveyance solutions that help reduce line changeover time and improve line efficiency.

RTE Food Production Conveyors

Applications

Dorner offers solutions to meet the needs of every step in ready-to-eat food production. From incoming ingredient handling and cleaning to cutting and meal assembly, Dorner’s food processing conveyors help to reduce physical strain on employees, improve line efficiency, and maintain the highest level of product quality.

Applications Include:

- Bulky product transfers

- Product rinsing and cutting

- Automated inspection

- Refrigerated environment operations

- Meal kit assembly and packaging

Conveyor Insights

3 Factors to Know in Food Processing: A guide to Boosting OEE

This new ebook examines the various factors that go into the overall equipment effectiveness (OEE) of a production line, and how implementing intelligent sanitary conveyor solutions can boost OEE and improve production.

Dorner Helps Ready-Made Food Producer Keep up with Demand

With a focus on producing reliable, handmade quality products, the new processing line was a move in response to growing business at Sandridge Food Corp. of Medina, Ohio, while continuing to enhance their customers’ reputations.

History of Ready-to-Eat Foods and Future Market Opportunities

Dorner and Garvey teamed up to bring customers the new AquaGard GT. Featuring a flexible chain belt and modular design for easy line integration, this system is the perfect solution for machine infeed and outfeed, and adds efficiency to every food packaging line.

Contact the Conveyor Experts!

Our team is standing by to answer any questions you may have and help you improve your ready-to-eat food production line with a sanitary stainless steel conveyor system.

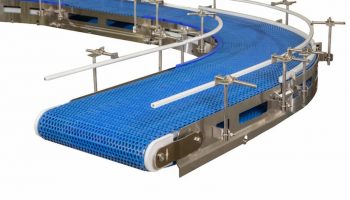

AquaGard Conveyors

AquaGard conveyors are BISCC-approved and designed for dry wipe-down and low-pressure wash applications. These conveyors are perfect for packaged pet foods, machine infeed and outfeed, and canning processes.

AquaPruf Conveyors

Rated for high-pressure and chemical washdowns, these conveyors are designed for the highest level of sanitation. AquaPruf conveyors are the premier choice for handling dairy, raw ingredients, ready-to-eat foods, and bulk produce and grains.

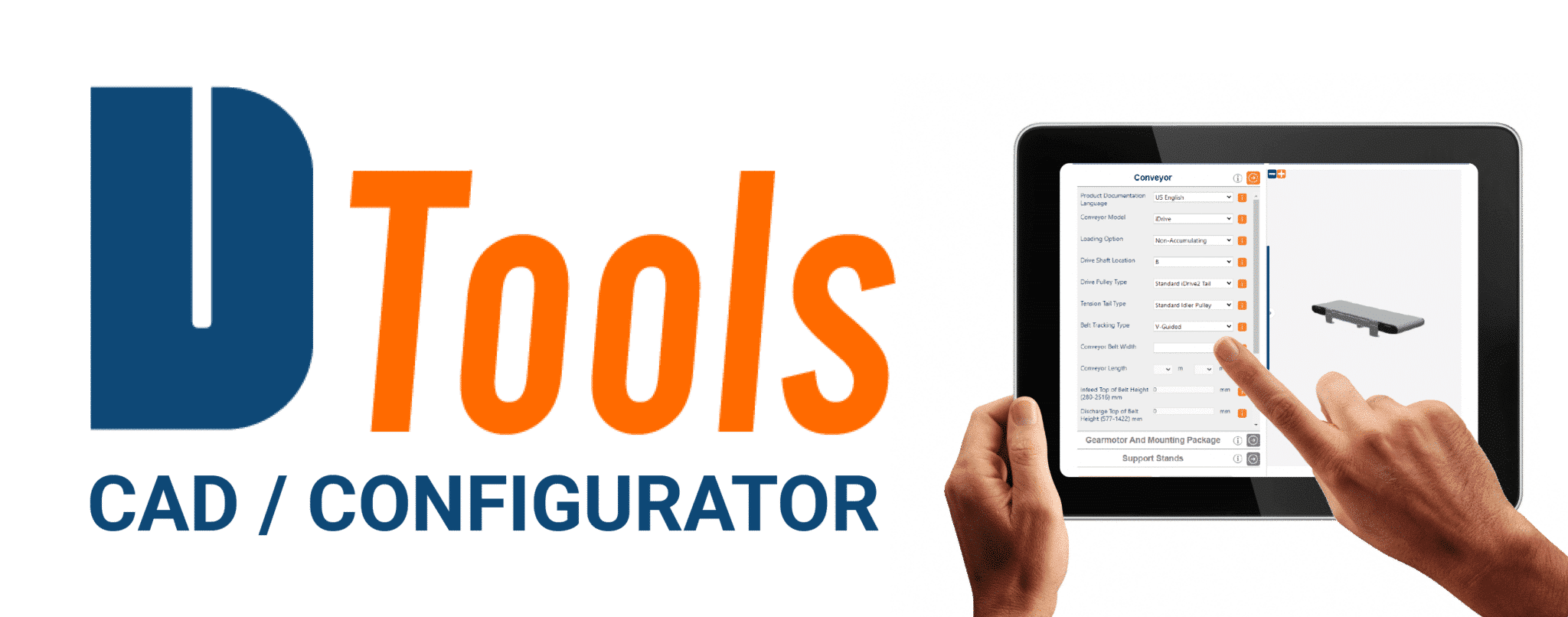

Sign up for DTools to start configuring your custom conveyor.

Find out how to optimize your production line. Fill out the form below to download our eBook!

Create your own custom conveyor with Dorner s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy