Small Conveyors

Features of Small Conveyors:

- Belt widths: 1 inch (25 millimeters) to 24 inches (610 millimeters).

- Conveyor lengths: 18 inches (457 millimeters) to 250 feet (76 meters).

- Load capacities: products weighing less than 15 pounds (6.8 kilograms) and ranges up to 600 pounds (272 kilograms).

- Belt speeds: Ranges from 10 feet per minute (3 meters per minute) up to 400 feet per minute (122 meters per minute).

A Wide Range of Small Conveyors

Dorner offers a wide range of small conveyors designed to move parts and product of all sizes, shapes and weights. Our small conveyors are available in belt widths as slim as 1¾ inches (44 millimeters), useful in conveying small product such as pharmaceutical drugs and perfume bottles, to larger widths up to the task of moving large boxes.

Our offerings are certain to meet your business’ needs, with our small conveyors available in standard options as well as tailor-made customized conveyor solutions to meet your business’ application needs. Small conveyors are also referred to as small part conveyors and small portable conveyors.

Small Conveyors Offered

by Dorner

2200 Belted

Conveyors

Featuring a rigid and robust single-piece frame that reduces the number of needed stands, Dorner’s 2200 Series Belted Conveyors are designed for small- to medium-size part handling. They are generally used for automated and manual assembly; inclines and declines; industrial applications; packaging; part accumulation, infeed and outfeed; precision part movement; and small-part handling, positioning and transfers.

Our 2200 Series Belted Conveyors feature the industry’s most-compact drive, saving space and decreasing integration time in our customers’ facilities while improving efficiency and productivity. A Universal T-Slot enables fast and easy attachment of accessories and guiding, and an optional nose bar can ensure product transfer at up to 200 feet per minute.

2200 Modular Belt Conveyors

Our low-profile 2200 Modular Belt Conveyors, featuring a plastic chain, are suited for applications in the assembling, general manufacturing, metalworking and packaging industries.

Common small-belt conveyor applications include part accumulation, small-part transfers and small- to medium-part handling. With an open frame design, Dorner’s 2200 Modular Belt Conveyors are ideal for water and chemical drainage as well as air cooling.

These small conveyors’ sleek profile means they’re able to fit in tight spaces and even be positioned under machinery. They can be operated at speeds of up to 250 feet per minute. An optional nose bar can convey product at up to 175 feet per minute.

2200 Precision Move Conveyors

Dorner’s 2200 Precision Move Conveyors are ideal for accurate small part handling and positioning, automated and manual assembly, machine integration, robotic pick-n-place, precision indexing, precision automation and part movement, and timed conveying. These small conveyors are looked to when customers’ applications require accurate alignment of time and distance.

Our 2200 Precision Move Conveyors can run at speeds as high as 370 feet per minute and bear loads of up to 200 pounds, making them highly efficient machines.

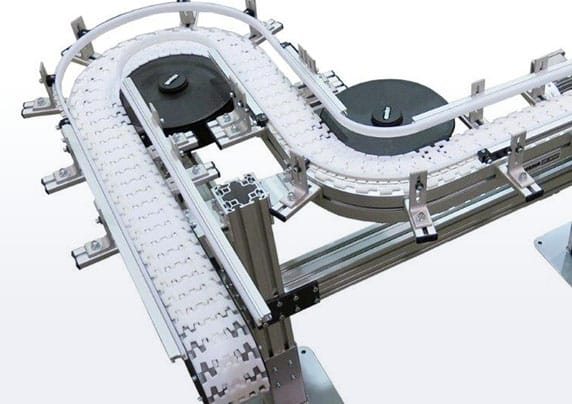

FlexMove Conveyors

Dorner’s FlexMove Conveyors family includes several small conveyors. Our FlexMove Conveyors are best for accumulation, assembly automation, buffering, complex configurations and curves, jogs, incline and decline. These small part conveyors are also suited for elevation changes, long lengths, machine conveyance, packaging, part handling, transfers and tight spaces. Because they are designed to handle multiple curves and inclines-declines on a single unit, FlexMove Conveyors are ideal for facilities in the assembly automation, medical, life sciences, packaging and processing industries. Businesses seeking small conveyors in this category often choose from our 45 mm, 65 mm, 85 mm and 105 mm models.

Dorner’s FlexMove Conveyors category also includes our FlexMove Alpine Conveyors. These small conveyors feature a spiral configuration that is often used as an accumulation or elevating buffer zone between machines. It is also utilized as a process step for cooling or drying parts or product and for line balancing and product-changeover purposes. Moreover, Dorner’s FlexMove Alpine Conveyors may be set up as an elevating or lowering system using a single or double serpentine configuration. These small conveyors can also serve as in-line accumulators, with entry and exit positioned at different levels, or as an in-line or off-line accumulator, with entry and exit on the same level.

AquaGard 7200 and 7300 Conveyors

Dorner’s AquaGard 7200 Conveyors and AquaGard 7300 Conveyors are sanitary conveyors, with the former rated for low-pressure washdown and the latter rated for high-pressure washdown, both with soap and water cleaners. They are designed to withstand loads up to 60 pounds, with belt speeds reaching speeds as high as 264 feet per minute.

Our AquaGard 7200 & 7300 Conveyors’ V-Groove frame with guided belt ensures accurate tracking. A Wedge-Lok system provides impact protection. The streamlined design of these small conveyors makes it possible to place it in spaces where other conveyors simply cannot fit. This construction enables fast and simple cleaning.

Dorner’s AquaGuard sanitary conveyors are built to promote hygienic design. They meet sanitary standards of the Baking Industry Sanitary Standards Committee (BISSC), 3A, USDA and other FDA regulations.

1100 Belt Conveyors

Dorner’s 1100 Miniature Belt Conveyor is known for being North America’s smallest-profile conveyor. This extremely small portable conveyor is exceptional for small or lightweight product movement and is used widely in the medical, life sciences and pharmaceutical industries.

Our 1100 Belt Conveyors feature a low-profile height that can be highly advantageous in facilities where space is at a premium, freeing up valuable machine and/or employee space. The small roller diameter allows for smooth transfers of small parts.

Small Conveyor Applications

For Specific Industries

Let’s have a look at which of Dorner’s small part conveyors work best for specific industries and applications.

General Product Handling

- 2200 Series Conveyors, particularly our 2200 Belted Conveyors, 2200 Modular Belt Conveyors and 2200 Precision Move Conveyors.

- FlexMove Conveyors (45 mm, 65 mm, 85 mm and 105 mm sizes) and FlexMove Alpine Conveyors.

- Dorner’s 3200 Series Conveyors are beneficial to convey larger products.

Food Processing

- AquaGard 7200 and AquaGard 7300 Conveyors.

- For larger items, particularly in the food processing industry, our AquaPruf 7400, AquaPruf 7600 and AquaGard 7350 Conveyors are favored, although these models generally exceed the size of small conveyors.

Robotics & Automation

- 2200 Series Conveyors.

- 2200 Series UR+ Solutions – 2200 Series conveyors are a certified UR+ Solution that simplifies robot and conveyor integration for an array of automated applications.

- For larger items, our 3200 Series Conveyors are preferred.

Packaging

- 2200 Series Conveyors, particularly our 2200 Belted Conveyors and 2200 Modular Belt Conveyors.

- FlexMove Conveyors (45 mm, 65 mm, 85 mm and 105 mm sizes) and FlexMove Alpine Conveyors.

- Dorner’s AquaGard 7350 and 3200 Series Conveyors are advantageous when working with larger items.

Pharmaceutical & Medical

- 2200 Series Conveyors.

- 1100 Series Conveyors.

Common Questions About Small Conveyors

What sizes do you offer?

Dorner’s small conveyors are available in a wide range of sizes and can be customized for your application(s).

Our 2200 Belted Conveyors, for example, are available in widths from 1¾ inches (44 millimeters) to 24 inches (610 millimeters) along with lengths of 1½ feet (457 millimeters) to 24 feet (7,315 millimeters).

Additionally, our 1100 Miniature Belt Conveyors, for example, come in belt widths of 1¾ inches (44 millimeters), 3¾ inches (95 millimeters), 6 inches (152 millimeters), 8 inches (203 millimeters) and 10 inches (254 millimeters) as well as lengths of 10.63 inches (270 millimeters) to 72 inches (1,829 millimeters) in ⅛-inch (3-millimeter) increments.

How long is your warranty?

Dorner proudly engineers and tests all our conveyor designs to ensure our customers experience trouble-free performance. We offer an industry-leading 10-year limited warranty to the original purchaser against material and workmanship defects under normal use, proper maintenance and cleaning. We will repair or replace defective parts.

What size product will fit on the belt?

Because Dorner’s small conveyors feature belt widths of various sizes—from as narrow as 1¾ inches (44 millimeters) to as wide as 24 inches (610 millimeters)—the size of parts and product that belts will accommodate will vary significantly.

Additionally, different belt widths can withstand different product weights, with the maximum weight accommodated being 150 pounds.

Can these small conveyors be combined with other conveyors?

Yes, some of our small part conveyors can be combined with other conveyors. A case in point is our FlexMove Alpine Conveyors, whose spiral configuration can be used as an accumulation or elevating buffer zone between machines. It can also be used as a process step for cooling or drying parts or product, for line balancing and product-changeover purposes and as an elevating or lowering system.

If you have questions about whether a specific small portable conveyor can be combined with other conveyors, please contact us by phone, email or chat.

CONTACT USHow portable are these conveyors?

Many of Dorner’s small roller conveyors are valued for their low profiles and quick and easy cleaning as well as their portability. Some of our small conveyors such as our 1100 Miniature Belt Conveyor may be as short as just 10.63 inches (270 millimeters)—making them ultraportable—to as long as 24 feet (7,315 millimeters), as is the case with our longest 2200 Belted Conveyor.

Additionally, Dorner offers casters to help make moving our conveyors much easier and faster.