It’s no surprise that time is often of the essence when it comes to designing and building a new machine. Hudson-Sharp recently validated that statement during the design of a special machine to add a closure mechanism to pre-made pouches. To help save time, the company turned to Dorner Mfg. Corp. to design the in-feed conveyor system – a move that freed up Hudson-Sharp engineers to allocate additional time on engineering the more critical aspects of the machine.

Green Bay, Wis.-based Hudson-Sharp is a manufacturer of plastic bag, pouch, and re-closable bag machine technologies. Its product offering includes plastic film converting equipment to make a variety of flexible packaging, plastic bags and pre-made pouch styles for bread, merchandise, hygiene, deli, large format, stand-up and other applications. In 2009 the company was acquired by Thiele Technologies, which is part of the Barry-Wehmiller Family of Companies.

The purpose of this specialty machine called a post applied slider is to add a closure mechanism to the top of existing large format flexible pouches and bags. While there are machines that do apply closure mechanisms to smaller pouches, there is a growing market for a machine to perform this process on large format pouches measuring as tall as 36 inches, said Moroni Mills, marketing communications specialist, Hudson-Sharp.

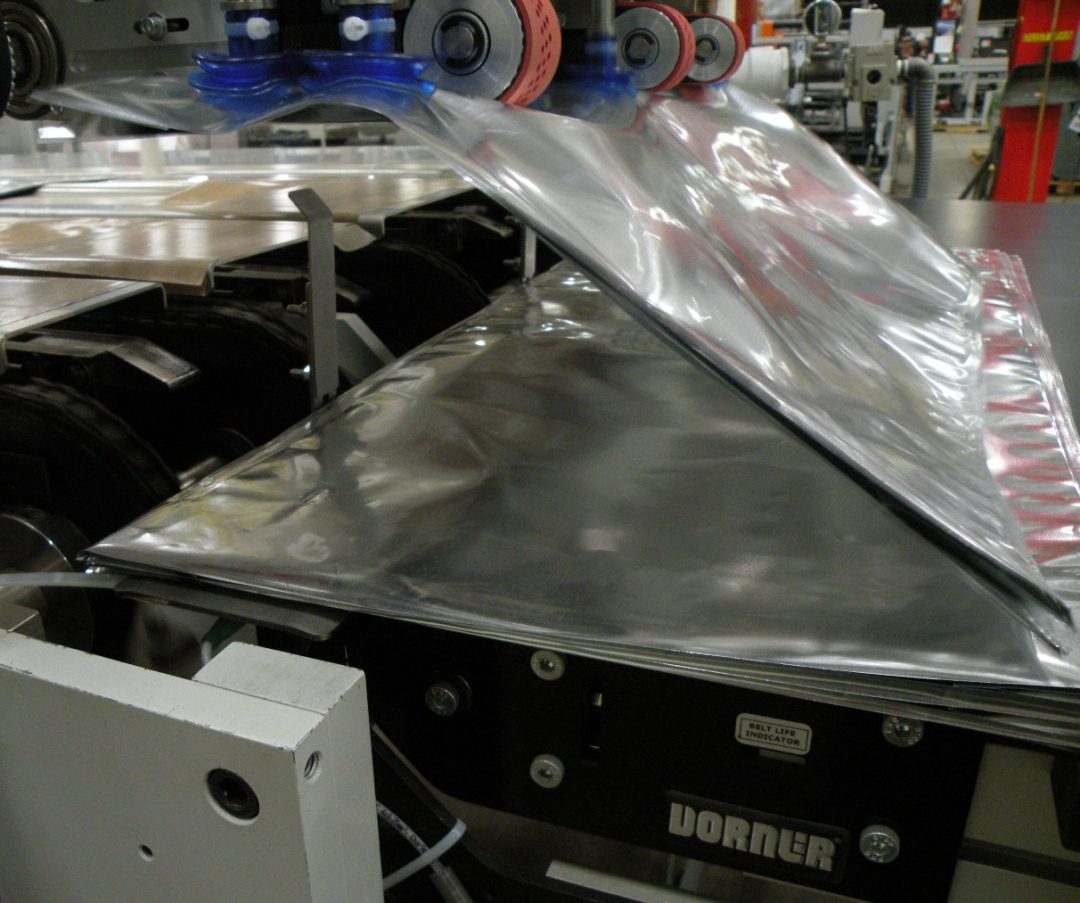

The process starts as stacks of pouches are placed on the conveyor either manually or through an automated process. The pouches are picked one at a time off a Dorner 3200 Series conveyor by an overhead vacuum transfer assembly. Multiple stacks of pouches can be placed on the conveyor at one time for picking; the conveyor is indexed toward the machine moving a new stack in position for continuous product flow. Since the pouches being modified have a slick plastic finish, it’s important that the conveyor belt had the proper coefficient of friction to avoid slippage. During the specification process, Dorner sent Hudson-Sharp a selection of belt types so they could evaluate which belt would best move the pouches.

“It was nice that Dorner sent us several types of friction belting, and with their input, we determined which one would work best for the plastic we were moving,” said Kristina Vogt, project engineer, Hudson-Sharp. “As an engineer, I really appreciate all the belt options available to me. This helped eliminate a lot of the guess work by knowing we were ordering the right belt ahead of time.”

After the pouches are picked off the conveyor, they are correctly orientated and properly spaced in preparation for the addition of the closure mechanism.

The 3200 Series in-feed conveyor, measuring 10 feet long by 4 feet wide, is a low-profile conveyor that’s designed specifically for applications involving part transfers and accumulation and precision part movement. It comes with V-guided belts for belt tracking, and rack-and-pinion tensioning for easy belt changes and adjustments. Dorner can build and ship a 3200 Series conveyor system, to exact customer specifications, in less than five days from time of order.

The decision to use Dorner for the in-feed conveyor was a suggestion made to Vogt by colleagues at one of the Thiele Technologies companies in Minnesota, who had used the conveyors for similar projects. Vogt said they occasionally design and build conveyors in house for certain applications within their machines, but for this project, she went with the recommendation to save time.

“One of the reasons why we used Dorner was that it decreased the amount of development time for the project,” Vogt said. “I had my engineers drawing other parts of the machine that needed more attention, and I just ordered the conveyor and that part component was done. I don’t have to have my engineers spend time designing that part. The conveyor works well and was cost effective.”

The machine can handle up to 60 bags per minute and takes about 16 weeks for installation from the time of order. The conveyor was sold to Hudson-Sharp through Braas Automation Components, Systems, & Solutions, an Eden Prairie, Minn.-based Dorner distributor.