Miniature conveyors are conveyors built as small as they come. And despite their space-saving sizes, these conveyors aren’t short on features. Dorner’s mini conveyors are designed to move small parts and lightweight product safely and efficiently.

Our miniature conveyor belt systems are perfect for transporting pharmaceutical drugs, surgical supplies, respiratory masks, syringes, stents, eyesight glasses and small bottles, for example, making them especially valuable to companies operating in the life sciences, medical and pharmaceutical industries.

Let’s explore key features of mini conveyors and then take a look at several types of miniature conveyors offered by Dorner.

Features of Miniature Conveyors

Dorner’s mini conveyors are designed with different sizes, speeds and other features in mind. The following information serves as a snapshot of some common features yet reveals a range of specifications to help give customers a vision for how mini conveyors might work in their businesses.

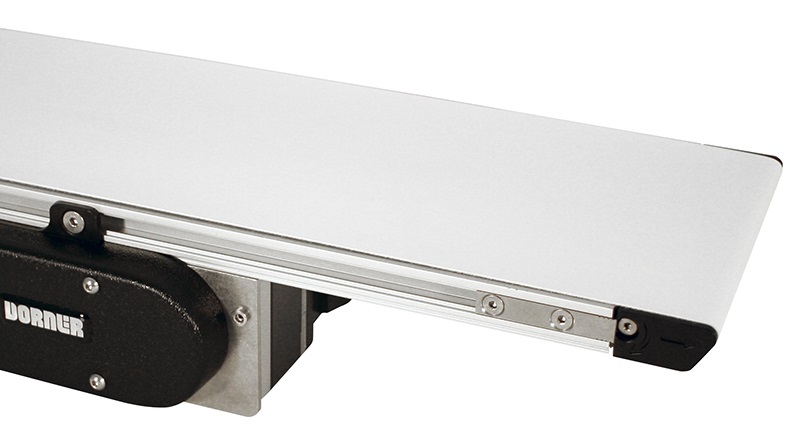

2200 Series Conveyors

2200 Series Conveyors

With a rigid and robust single-piece frame, Dorner’s 2200 Series Conveyors are suited for handling small to medium-size parts. These mini conveyors are generally used for:

- Automated and manual assembly

- Inclines and declines

- Industrial applications

- Packaging

- Part accumulation, infeed and outfeed

- Precision part movement

- Small-part handling, positioning and transfers

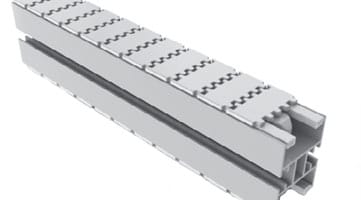

FlexMove FK 45 mm

Dorner’s FlexMove Conveyors include a miniature conveyor. Our FK 45 mm Aluminum Conveyor model features a compact and clean design and is built to move small items, from perfume bottles to pharmaceutical bottles, quickly.

This mini conveyor belt utilizes a plastic chain that allows for horizontal and vertical change of direction. In addition to the standard types, several special purpose chains are available. The FK 45 mm Aluminum Conveyor is used in the life sciences, medical, packaging and processing industries.